Chapter 6 Calibration

Page 6-3

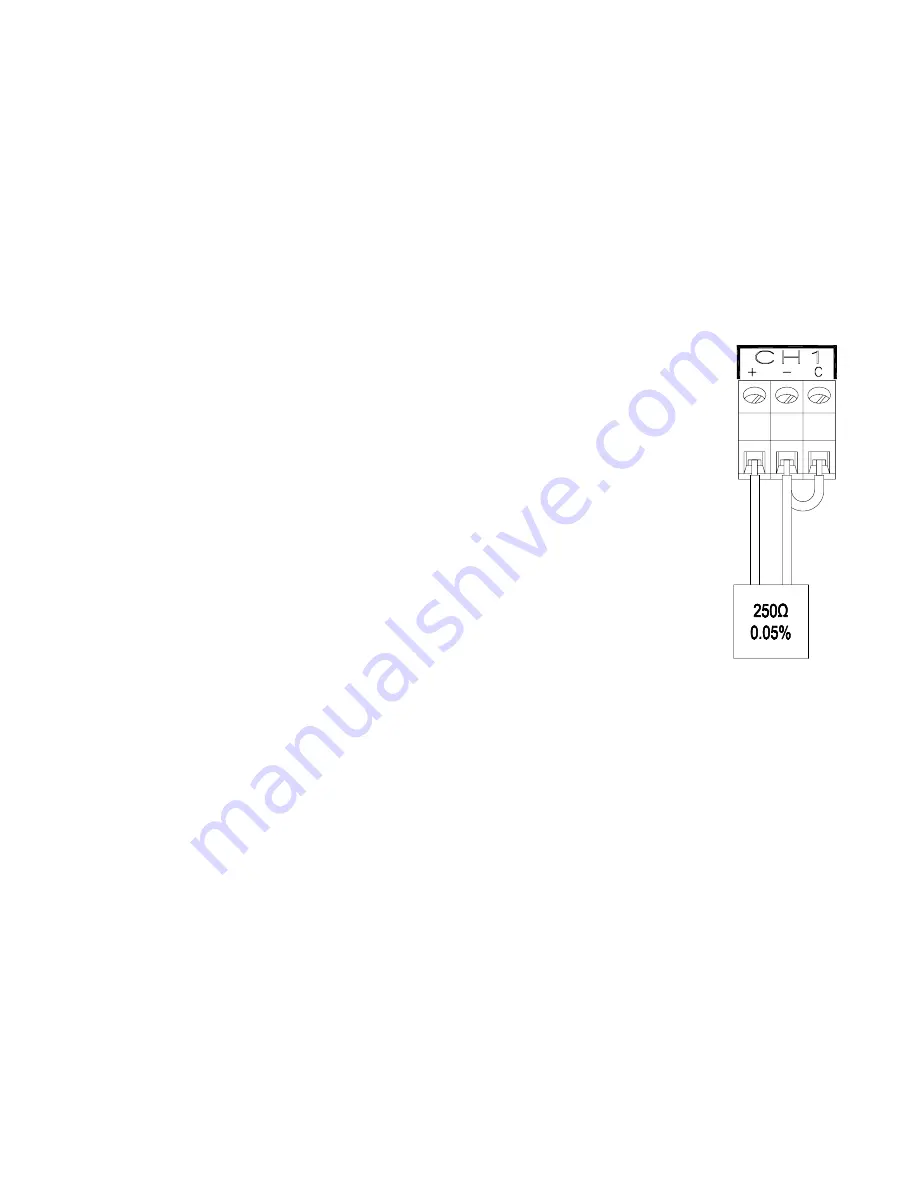

Figure 6-1

Calibration

Resistor

Connection

6.4 RTD Current Calibration

The ADC current source is used for RTD measurements and needs calibration for the RTD’s.

6.4.1 Calibrating the RTD Current

The following procedure contains step-by-step instructions on Calibrating the Current source. A 250

Ω

±0.05%

resistor must be connected across the

+

and

-

terminals of a free input and the current source return path

C

must be connected to the

-

input terminal. The Recorder then applies 1mA of Current through the resistance to

Calibrate Current. These programming steps are discussed in menu order.

NOTE:

Before Calibrating Currents, ensure that the Zero Calibration and 1.25 Volt Scale range has been

calibrated per the previous sections as this will affect the accuracy of Current Calibration.

6.4.1.1 Connecting Resistance

Select a free set of input terminals on the rear of the unit, or remove any connections

from the set of terminals to be used. Connect the 250

Ω

±0.05% resistor across the

+

and

-

terminals of this input and connect the Current source return path

C

to the

-

input

terminal (see Figure 6-1).

6.4.1.2 Calibrating the RTD Current

To Calibrate the RTD Current:

From the Hidden Menu use the

UP (

↑↑↑↑↑

)

or

DOWN (

↓↓↓↓↓

)

button to select

ADC control

and

then press the

ENTER

button. The only available option is

Cal Adc

so just press the

ENTER

button. Use the

UP (

↑↑↑↑↑

)

or

DOWN (

↓↓↓↓↓

)

button to highlight

Cal currents

and

press the

ENTER

button. You will be prompted with “cal input? X”. Use the

UP (

↑↑↑↑↑

)

or

DOWN (

↓↓↓↓↓

)

button to select the channel input number (1, 2, 3, 4, 5 or 6) to which the

resistor is connected and press the

ENTER

button. You will be prompted with “APPLY

[resistor value]”. To allow the Recorder to detect the actual value of the Current, press

the

OK?

button. A window will appear showing the reading of the Current connected.

Press the

CAL.

button. You will then be prompted with “Are You Sure?”. Press the

CAL.

button to continue the calibration or the

NO

button to abort. If the

CAL.

button is

pressed, the Recorder program will store the adjusted value from a nominal 1mA of

Current. Calibration of Currents is complete.

6.5 Calibration Recall

If the calibration equipment listed above is not available, the factory Calibration for the Zero Calibration and Scales

(sections 6.2 and 6.3) can be recalled

. All channels will be recalled.

To Recall the factory Calibration:

From the Hidden Menu use the

UP (

↑↑↑↑↑

)

or

DOWN (

↓↓↓↓↓

)

button to select

ADC control

and then press the

ENTER

button. The only available option is

Cal Adc

so just press the

ENTER

button. Use the

UP (

↑↑↑↑↑

)

or

DOWN (

↓↓↓↓↓

)

button

to highlight

Cal recall

and press the

ENTER

button. You will be prompted with “Are You Sure?”. Press the

YES

button to retrieve the factory Calibration settings or the

NO

button to abort.

6.6 Factory Set

This option is for factory use only and overwrites the default factory Calibration constants with the current ones in

the analog board. This makes the Current Calibration constants the default, and it is these values that will be

recalled when attempting to restore factory Calibration.

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com