EN-

5000 Series Indicators

4. OPERATION .............................................................................................................................................EN-43

4.1 Turnng Indcator On/Off ............................................................................................................................EN-43

4.2 Zero Operaton .........................................................................................................................................EN-43

4.3 Manual Tare ............................................................................................................................................EN-43

4.4 Pre-Set Tare ............................................................................................................................................EN-43

4.5 Auto-Tare ................................................................................................................................................EN-43

4.6 Changng Unts of Measure .......................................................................................................................EN-44

4.7 Prntng Data ...........................................................................................................................................EN-44

4.8 Applcaton Modes ...................................................................................................................................EN-44

4.8.1 Weghng .....................................................................................................................................EN-44

4.8.2 Parts Countng .............................................................................................................................EN-44

4.8.3 Percent Weghng .........................................................................................................................EN-45

4.8.4 Check Weghng ...........................................................................................................................EN-46

4.8.5 Dynamc Weghng .......................................................................................................................EN-47

5. SERIAL COMMUNICATION ..........................................................................................................................EN-48

5.1 Interface Commands ................................................................................................................................EN-48

5.2 Output Format .........................................................................................................................................EN-49

5.3 Prntouts .................................................................................................................................................EN-49

6. LEGAL FOR TRADE ...................................................................................................................................EN-51

6.1 Settngs ..................................................................................................................................................EN-51

6.2 Verfcaton ..............................................................................................................................................EN-51

6.3 Sealng ...................................................................................................................................................EN-51

7. MAINTENANCE .........................................................................................................................................EN-53

7.1 Model T51P Cleanng ...............................................................................................................................EN-53

7.2 Model T51XW Cleanng ............................................................................................................................EN-53

7.3 Troubleshootng .......................................................................................................................................EN-53

7.4 Servce Informaton ..................................................................................................................................EN-54

8. TECHNICAL DATA .....................................................................................................................................EN-55

8.1 Specfcatons ..........................................................................................................................................EN-55

8.2 Accessores and Optons ...........................................................................................................................EN-56

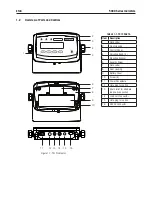

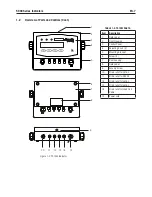

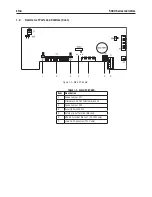

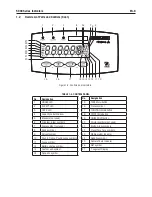

8.3 Drawngs and Dmensons ........................................................................................................................EN-57

8.4 Complance.............................................................................................................................................EN-58

TABLE OF CONTENTS (Cont.)

Summary of Contents for T51P

Page 1: ... 5000 Series Indicators Instruction Manual T51XW Indicator T51P Indicator ...

Page 2: ...ii ...

Page 63: ......