31

www.climacoolcorp.com

Space and Location Requirements

The most important consideration which must be taken

into account when deciding upon the location of air

cooled equipment is the provision for a supply of ambient

air to the condenser, and removal of heated air from the

condenser area . Where this essential requirement is not

adhered to, it will result in higher head pressures, which

cause poor operation and possible eventual failure of

equipment . Units must not be located in the vicinity of

steam, hot air or fume exhausts .

Another key consideration is that the unit should be

mounted away from noise sensitive spaced and must

have adequate support to avoid vibration and noise

transmission into the building . Units should be mounted

over corridors, utility areas, restrooms and other auxiliary

areas where high levels of sound are not an important

factor . Sound and structural consultants should be

retained for recommendations .

Consideration should also be made to make sure there is

sufficient space for removal/replacement of micro-channel

coils (when supplied) . A minimum of one unit width should

be allowed on the header end of the unit to provide

sufficient clearance.

Walls or Obstructions

The unit should be located so that air may circulate freely

and not be recirculated. For proper air flow and access, all

sides of the unit should be a minimum of “W”* away from

any wall or obstruction . It is preferred that this distance

be increased whenever possible . Care should be taken to

see that ample room is left for maintenance work through

access doors and panels . Overhead obstructions are not

permitted . When the unit is in an area where it is enclosed

by three walls, the unit must be installed as indicated .

Figure 19 - Clearance from Walls or Obstructions

Air Flow

W

W

MIN .

*W = Total width of the condenser

Remote Condenser

Multiple Units

For units side by side, the minimum distance between units

is the width of the largest unit . If units are placed end to

end, the minimum distance between units is 4 feet .

Figure 20 - Clearance for Multiple Units Placed Side by Side

Air Flow

Air Flow

W

MIN .

W

W

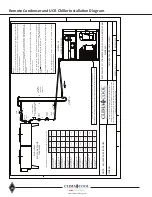

Units in Pits

The top of the unit should be level with the top of the pit,

and side distance increased to “2W” .

If the top of the unit is not level with the top of the pit,

discharge cones or stacks must be used to raise discharge

air to the top of the pit . This is a minimum requirement .

Figure 21 - Clearance for Units in Pits

Air Flow

10 FT . MAX

Stack

Supplied by Others

2W

MIN .

2W

W

MIN .

Decorative Fences

Fences must have 50% free area, with 1 foot undercut, a

“W” minimum clearance, and must not exceed the top of

the unit . If these requirements are not met, unit must be

installed as indicated for “Units in pits” .

Figure 22 - Clearance for Fence Enclosures

W

MIN .

W

MIN .

W

Air Flow

Clearance for Fence Enclosures

1 FT . MIN

Summary of Contents for CLIMACOOL UCR 30

Page 19: ...17 www climacoolcorp com Voltage Phase Monitor Wiring Diagram...

Page 29: ...27 www climacoolcorp com Evaporator Water Pressure Drop Charts...

Page 30: ...28 www climacoolcorp com Glycol Performance Adjustments Factor Charts...

Page 78: ...76 www climacoolcorp com Wiring Diagram...

Page 79: ...77 www climacoolcorp com Wiring Diagram...

Page 80: ...78 www climacoolcorp com Wiring Diagram CoolLogic Control Panel...

Page 81: ...79 www climacoolcorp com Wiring Diagram CoolLogic Control Panel...