68

www.climacoolcorp.com

Stainless Steel Strainer Option

What is Water Hammer?

Water hammer is a phenomenon that can occur in fluid

systems with long pipes . Water hammer is a rapid change

of pressure caused by a rapid change in velocity. If the flow

has been abruptly shut off downstream, the pressure in the

entire system is raised very quickly .

What Causes Water Hammer?

Any action that can cause a rapid change in the velocity

of the flow can set off a water hammer, such as closing a

downstream valve, pump stoppage, etc . Typically, for short

lengths of pipe (below 500 feet) downstream valves that are

closed within 1/10 of a second can generate water hammer .

What Can Water Hammer Do?

Pressure spikes from water hammer can raise fluid pressures

to dangerously high values . These pressure spikes can cause

serious damage to valves, pipes, strainers, joints, etc . The

CS strainer is rated to an absolute maximum pressure of 150

psi for bolted lid models, and 125 psi for clamped lid models .

A water hammer pressure spike that raises the pressure

higher than the maximum rated pressure may result in

strainer damage, voiding the manufacturer’s warranty .

What Can I Do to Prevent Water Hammer?

There are certain precautions that can be taken to prevent

or decrease the effect of water hammer. The addition of a

surge tank or accumulator fitted with a suitable pressure

relief valve strategically located within the water system

may provide adequate protection against the effects from

water hammer . Careful attention should be given to the

design and control strategy for valves and pumps so the

actions do not invite a water hammer .

Stainless Steel Strainer Options

Automatic Timer Flush (ATF) Package Option

The ATF-EA-1.5 flush valve package provides an automatic

method for flushing away the debris collected in the strainer’s

reservoir . The power supply and timer controls for the valve

package are housed inside the ATF control box . The ATF

controls can be pre-programmed to set the flushing duration

and the time interval between flushes.

System Components

1 .

Timer based valve controller: (see Figure 29) sets the

flush duration (length of the flush) and the flush interval

(time between flushes).

2 .

Electric ball valve: designed for dirty water use (see

Figures 30 and 31) .

Figure 29

A

GREEN POINTER

INNER RING

(LENGTH OF FLUSH)

(FACTORY SET AT

8-SECONDS)

RED POINTER

OUTER RING

(TIME BETWEEN

FLUSHES)

(FACTORY SET AT

24-HOURS)

Figure 30

B

[email protected] POWER

FROM PDA OR 120V PLUG

IN TRANSFORMER

OPEN/CLOSE

INDICATOR

COVER-PLATE SCREWS

(4) IN CORNERS OF BOX

(TIMER BASED VALVE

CONTROLLER)

CONTROL SWITCH

Figure 31

Valve Specifications

A . Water-resistant polypropylene motor case

B . High torque motors with perma-lube gears

C . Open and close indicator

D . Stainless steel ball valve and hardware

E . Auto reset circuit breaker

F . 90° bi-directional rotation

G . Controller case

Summary of Contents for CLIMACOOL UCR 30

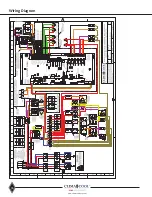

Page 19: ...17 www climacoolcorp com Voltage Phase Monitor Wiring Diagram...

Page 29: ...27 www climacoolcorp com Evaporator Water Pressure Drop Charts...

Page 30: ...28 www climacoolcorp com Glycol Performance Adjustments Factor Charts...

Page 78: ...76 www climacoolcorp com Wiring Diagram...

Page 79: ...77 www climacoolcorp com Wiring Diagram...

Page 80: ...78 www climacoolcorp com Wiring Diagram CoolLogic Control Panel...

Page 81: ...79 www climacoolcorp com Wiring Diagram CoolLogic Control Panel...