13

www.climacoolcorp.com

Unit Placement

ClimaCool modular chillers must be installed in a

conditioned and dehumidified space. The minimum

foundation requirement for the ClimaCool chiller is a level

surface capable of bearing the combined operating weight

of the modules (see Physical Data - page 5) .

Service Access

The recommended service clearances are 36” for front

service access, 18” height clearance for service and 30” for

rear service access as identified in the Recommended Service

Clearances on page 11 . Local building or electrical codes may

require additional clearance – consult applicable codes .

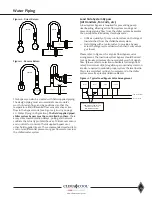

Draining

When performing standard maintenance procedures such

as flushing a heat exchanger, it will be necessary to close

off a section of a module. ClimaCool modular chillers offer

optional water isolation valves for this purpose . Access

to a floor drain is helpful when performing standard

maintenance procedures .

Warning: Water valves must be

reopened after flushing is complete.

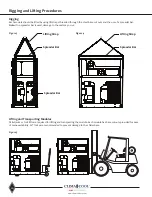

Assembling Modules

ClimaCool recommends locking down the chiller to a

concrete base, or to three (3) 4” base mounting rails, using

the six (6) bolt holes provided in each base pan . Although

the compressors are installed on anti-vibration mountings,

further isolation of the chiller from the structure is

recommended by installing vibration — eliminating springs

or pads under the base rails on which the chiller will rest

(see page 10 – Mounting Rail and Vibration Isolation) . One

end of the modules should be chosen as the reference

module and carefully located .

Field installed mounting accessories are provided for

adjoining each module .

• Header grooved coupling kits containing two (2) grooved

couplings with gaskets .

• Mounting hardware kit containing necessary bolts,

spacers, nuts and washers .

• Header bank end cap kit containing two (2) grooved

couplings with gaskets and two (2) end caps .

Unit Installation

Field installing the mounting hardware kit will assist with

alignment of the modules in a bank and eliminate offset

inconsistencies. The 1/2” mounting holes are provided on sides

of the unit base pan. The first module should be set, then

set the adjacent unit on mounting surface roughly aligned

1 ½ inches away from the first unit. While holding spacer in

place, work through first modules front base cutout to place

a washer and insert bolt through front mounting hole and

spacer . Repeat the process for the rear mounting hole . Line

up mounting hole of adjacent module with bolt from previous

module . Work through adjacent modules front base cutout

by placing a washer, split lock washer and nut . Using the

appropriate tools, tighten hardware assembly until seated .

Figure 8 - Hardware Kit

Figure 9 - Spacer Holes

END TO END SPACER HOLES

Summary of Contents for CLIMACOOL UCR 30

Page 19: ...17 www climacoolcorp com Voltage Phase Monitor Wiring Diagram...

Page 29: ...27 www climacoolcorp com Evaporator Water Pressure Drop Charts...

Page 30: ...28 www climacoolcorp com Glycol Performance Adjustments Factor Charts...

Page 78: ...76 www climacoolcorp com Wiring Diagram...

Page 79: ...77 www climacoolcorp com Wiring Diagram...

Page 80: ...78 www climacoolcorp com Wiring Diagram CoolLogic Control Panel...

Page 81: ...79 www climacoolcorp com Wiring Diagram CoolLogic Control Panel...