61

www.climacoolcorp.com

Refrigerant Charging

Once leak testing and evacuation are complete, refrigerant

charging may commence . Always refer to the unit

nameplate and guidelines within this section in order to

establish the quantity of refrigerant required .

IMPORTANT:

Always introduce refrigerant into a system using a charging

manifold with gauges, along with a refrigerant scale to

accurately weigh the refrigerant cylinder throughout the

entire charging process .

As noted in an earlier section, the

end user and installing contractor must provide and field

charge refrigerant R-410A.

CAUTION/ATTENTION

Never dispense refrigerant amounts

into the receiver which may exceed

its liquid holding capacity. The

refrigeration system in our model

UCR030 is equipped with 72

pound receivers (at 80% full). Both

refrigeration systems in models

UCR050 and UCR070 are equipped

with 84 pound receivers (at 80% full).

Jamais distribuer montants réfrigérant

dans le récepteur, qui peut dépasser

sa capacité de rétention liquide. Le

système de réfrigération dans notre

modèle UCR030 est équipé de 72

livres récepteurs (à 80 % complet).

Les deux systèmes de réfrigération

pour les modèles UCR050 et UCR070

sont équipés de récepteurs de 84

livres (à 80 % complet).

As much refrigerant as possible should be charged in this

manner until the receiver holding capacity is achieved, or

system pressures equalize preventing additional refrigerant

from being added . Even if system equalization occurs, it is

still possible to inject liquid refrigerant into the system by

placing the refrigerant cylinder into a luke warm water bath .

NO WARMER THAN 110°F.

WARNING/ADVERTISSEMENT

Cylinder pressures must be closely

monitored whenever a refrigerant

cylinder is being heated in ANY

manner. Allowing pressures to exceed

those for which the cylinder is rated

may result in cylinder rupturing,

personal injury and/or property

damage or even death.

Pression des cylindres doit être

surveillée étroitement chaque fois

qu’une bouteille de réfrigérant est

chauffe de toute manière. Permettant

des pressions supérieures à celles

pour lesquelles le cylindre est évalué

peut entraîner dans le cylindre une

rupture, des blessures corporelles

ou dommages matériels ou même

la mort.

Once system and refrigerant cylinder tank pressures have

equalized, it will be necessary to finish the refrigerant

charging process by gradually metering small bursts of liquid

refrigerant into the suction line of the compressor while it

is operating .

Refrigerant Charging Procedure

CAUTION/ATTENTION

Never attempt to vapor charge into

the system high side, whether the

compressor is ON or OFF. This may

result in refrigerant flowing from the

refrigeration system into the charging

cylinder. Cylinders can quickly be over

pressurized causing them to rupture

with resultant injury or property damage.

Ne jamais essayer de vapeur frais

dans le côté élevé du système, si le

compresseur est ON ou OFF. Cela

peut entraîner dans le réfrigérant

qui se jettent dans le système de

réfrigération dans le cylindre de charge.

Les bouteilles peuvent être rapidement

sursous la pression obligeant à rompre

avec les blessures qui en résultent ou

dommages matériels.

ATTENTION

Never dispense liquid refrigerant into the suction port of a compressor while it

is not running. If adding additional refrigerant is necessary, you must gradually

meter liquid refrigerant into suction port of the compressor ONLY WHILE THE

COMPRESSOR IS RUNNING and only through a metering valve.

The only exception to the above recommendations to meter

in liquid refrigerant into the suction line is the following:

Providing the ENTIRE contents of the refrigerant cylinder

is intended to be added to a refrigeration system . It is

perfectly acceptable to vapor charge from this cylinder into

the compressor suction line until all refrigerant is injected .

The amount of refrigerant required in a system depends on

the following:

•

Model size of the equipment .

•

The distance of the interconnecting lines between

the UCR module and the condenser section .

•

The specific head pressure control methods used for

low ambient operation .

•

What (if any) fan cycling controls are supplied with

the condenser .

•

Whether optional compressor unloading is possible

using hot gas bypass .

Refer to Tables 10 and 11 on page 62 as a guideline to

determine the total amount of additional refrigerant at

initial startup which accommodates all dependant variables

listed above . Although the charge in the table refers to a

winter charge, it is suitable for both winter and summer

operation . The total charge amount is also listed in the

job specific submittal data. The most accurate charge will

appear in the project submittals .

Summary of Contents for CLIMACOOL UCR 30

Page 19: ...17 www climacoolcorp com Voltage Phase Monitor Wiring Diagram...

Page 29: ...27 www climacoolcorp com Evaporator Water Pressure Drop Charts...

Page 30: ...28 www climacoolcorp com Glycol Performance Adjustments Factor Charts...

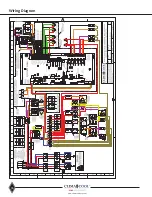

Page 78: ...76 www climacoolcorp com Wiring Diagram...

Page 79: ...77 www climacoolcorp com Wiring Diagram...

Page 80: ...78 www climacoolcorp com Wiring Diagram CoolLogic Control Panel...

Page 81: ...79 www climacoolcorp com Wiring Diagram CoolLogic Control Panel...