Napco iSecure Security System

All technical manuals are available in PDF format at

tech.napcosecurity.com

17

when mounted above sinks, when used in residential car

garages, and in other small, acoustically live rooms and

rooms where multiple sound can reflect and eventually

duplicate the glass

-

break frequency pattern. For occupied

-

area glass

-

break protection in such applications, the use of

shock sensors is recommended.

3.

Installing the unit on 24

-

hour loops will increase false

alarms. The ISEC

-

GLASSBREAK is recommended for

perimeter loops and is designed to function without false

alarms in occupied areas. On a 24

-

hour loop, which is

armed all day, all night, every day, the false alarm technol-

ogy will be pushed to its limit since some sounds in some

conditions can duplicate the points on the glass

-

break pat-

tern that the unit detects. Install the unit on a perimeter

loop, which is armed whenever the door and window con-

tacts are armed. For occupied

-

area installations, the ISEC

-

GLASSBREAK's false

-

alarm immunity is best in rooms

with only moderate noise.

4.

The unit detects the shattering of glass. As with all glass

-

break detectors, it may not consistently detect cracks in

glass or bullets that break through the glass or break out

the glass. Glass

-

break detectors should always be backed

up by interior protection.

TESTING

Preliminary

Use a Sentrol Model 5709

-

C hand

-

held tester (available sepa-

rately) to place the detector into its test mode and for all func-

tional testing.

Set the tester for tempered glass. Holding the tester speaker

directly over the sensor, activate the tester. The detector will

go into alarm (LED will come on for about 4 seconds), then go

into the test mode for one minute. While in the test mode, the

detector's LED will blink continuously. Extend test

-

mode time

by firing the tester at least once a minute.

Testing the Sensor

The 5709

-

C tester has a setting for each type of glass. The

tester should always be set for Tempered or Laminated glass

(either is correct and both have the same range) unless the

installer is certain that the glass to be protected is plate glass.

Holding the tester near the surface of the glass, aim the tester

at the detector and hold down test button. If drapes or blinds

are present, test with the hand

-

held tester behind the closed

drapes or blinds (do not use detector with heavy or lined

drapes). If the detector is mounted on the same wall as the

glass, point the tester at the opposite wall.

If the LED on the detector comes on for about 4 seconds when

the tester is triggered, the glass is within detection range. If the

LED does not come on but just continues to blink, reposition

the detector closer to the windows and retest. This may re-

quire the use of additional detectors in order to achieve the

desired coverage. In the unlikely event that the detector does

not respond within its stated range of coverage, check the bat-

tery in the tester; a new battery will likely restore range.

The ISEC

-

GLASSBREAK detector will automatically revert to

its normal operating mode approximately 1 minute after the

last test.

Note:

Room acoustics can artificially extend the range of a

glass

-

break sensor. The specified range of the ISEC

-

GLASSBREAK detector has been established for worst

-

case

conditions. While the sensor will likely function at additional

range, it may miss a minimum output break, or room acoustics

may be changed at some future time, bringing sensor range

back into normal 20' (6m) conditions. Do not exceed the rated

range of the sensor, regardless of what the tester shows.

Test

-

Mode Operation

The ISEC

-

GLASSBREAK ignores most false alarm sounds,

including glass break testers. In order to test the ISEC

-

GLASSBREAK detector, a test mode is used. In its test mode,

sensor processing of the glass

-

break pattern in the upper and

lower frequencies is disabled, thus the sensor is listening only

for the midrange frequencies, which the tester produces. It is

the midrange frequencies that determine sensor range.

In the normal operating mode, the LED does not blink unless

the sensor hears a loud sound. In normal operation, the ISEC

-

GLASSBREAK detector will not be tripped by the tester unless

the tester is held right up against the sensor.

Note:

Each time the detector goes into alarm, it also goes into

the test mode for one minute.

Hand

-

Clap Test

The ISEC

-

GLASSBREAK can be tested by the installer or the

end user while in its normal mode simply by clapping loudly

under the sensor. The LED will blink twice, but the detector will

not trip. This verifies visually that there is power to the detector

and that the microphone and circuit board are functioning. The

hand

-

clap activation is momentary so there is no appreciable

effect on battery life.

See page 46 for full programming information.

4. Install Glass

-

Break Sensors (cont'd)

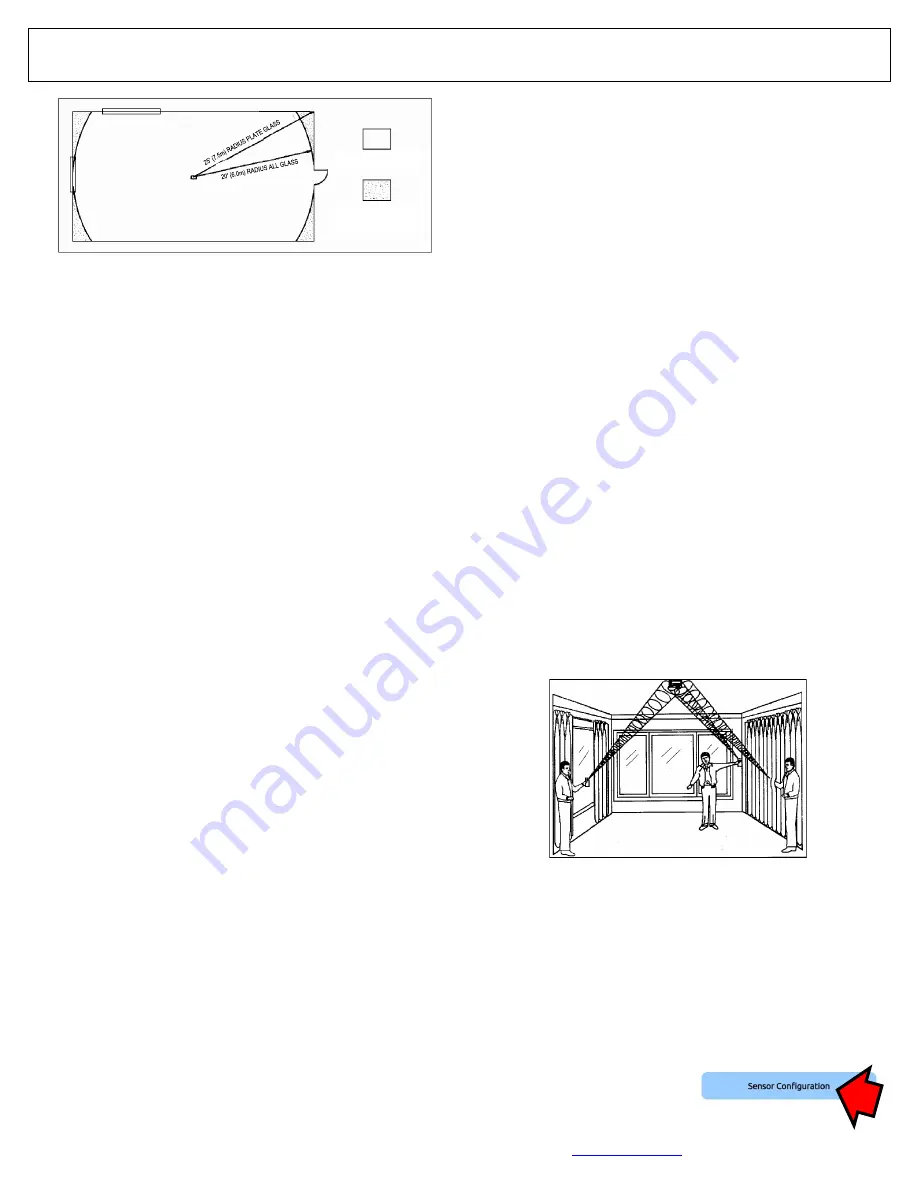

COVERAGE AREA ALL GLASS

ADDITIONAL COVERAGE AREA

FOR PLATE GLASS

Fig. 3. Typical coverage pattern for ceiling

-

mounted units.

Fig. 4. Testing the sensor.