User’s Guide DrafStation and Drafstation Pro

Chapter 3: Basics

60

AP-75730, Rev. 2.1, 19/01/2009

Step 7 :

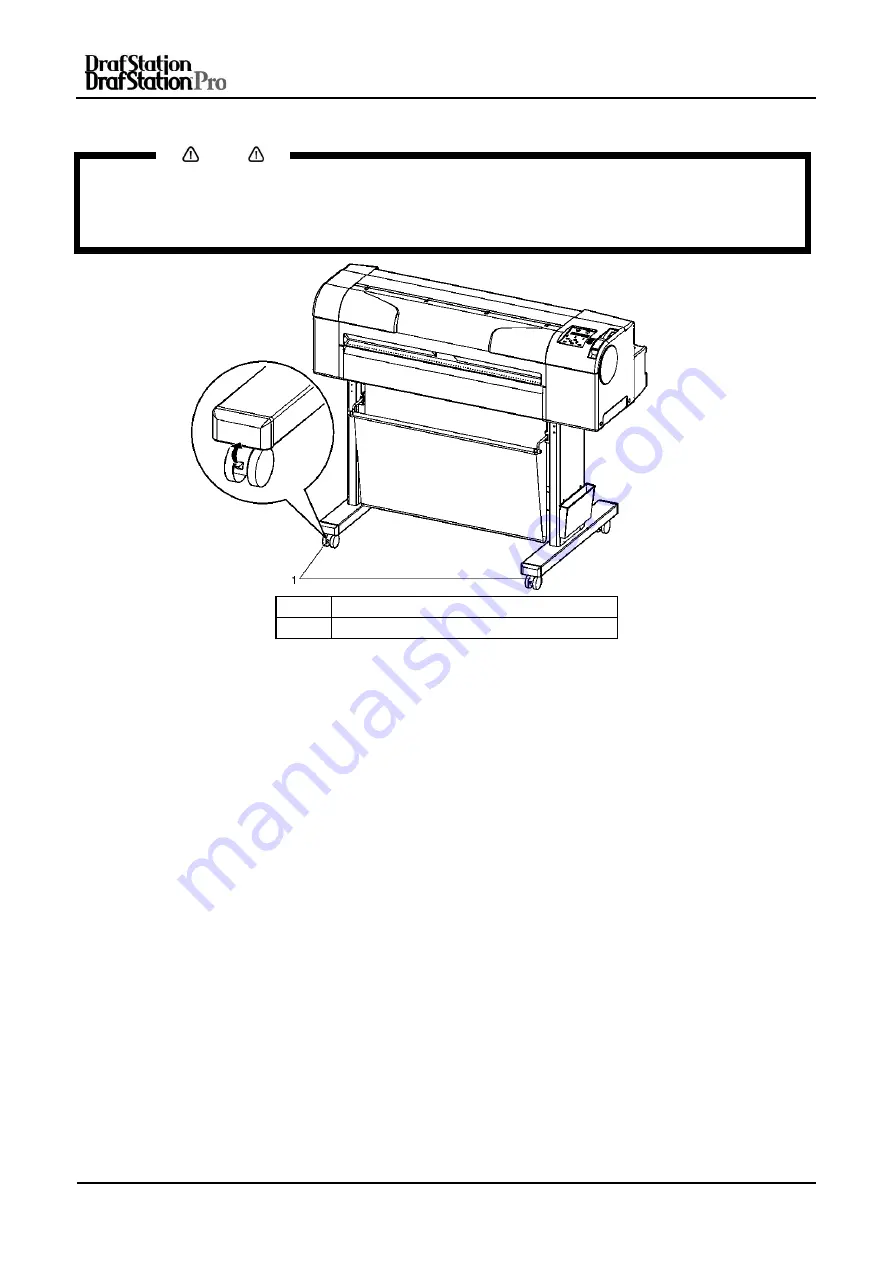

Release the lock of the caster and transfer the plotter.

Notes

•

The casters supplied with the dedicated stand are manufactured for a small transfer on a plain surface.

When moving the plotter outdoors, and in places with big step differences, than move the stand and

plotter separately.

•

Refer to the Installation guide.

N° Name

1 Caster

(2) Steps after transfer

After transfer, follow the steps below.

Step 1 :

Choose a suitable place for installation and place the plotter.

See

Installation guide

Step 2 :

Verify that the butterfly bolts fixing the stand with the plotter are not loosening.

Step 3 :

Connect all cables.

Step 4 :

Perform a nozzle check, and verify that there is no clogging in the plotter head.

Refer to: NozzleCheck”

Step 5 :

Perform a head alignment.

Refer to: “AdjustPlot “