76

- E

nglIsh

-

Operator’s manual

- Also adopt the following preventive and pro-

tective equipment:

• gloves resistant to mineral oils, with li-

ning;

• goggles, in case of splashes;

• aprons resistant to mineral oils;

• screens to protect against oil splashes.

m

ineral

oil

:

first

aid

proCedures

-

Swallowing: seek medical attention, providing

the characteristics of the type of oil swallo-

wed.

-

Inhalation: in case of exposure to high concen-

trations of fumes or mists, take the affected

person to the open air and seek medical

attention immediately.

-

Eyes: rinse with plenty of running water and

seek medical attention as soon as possible.

-

Skin: wash with soap and water.

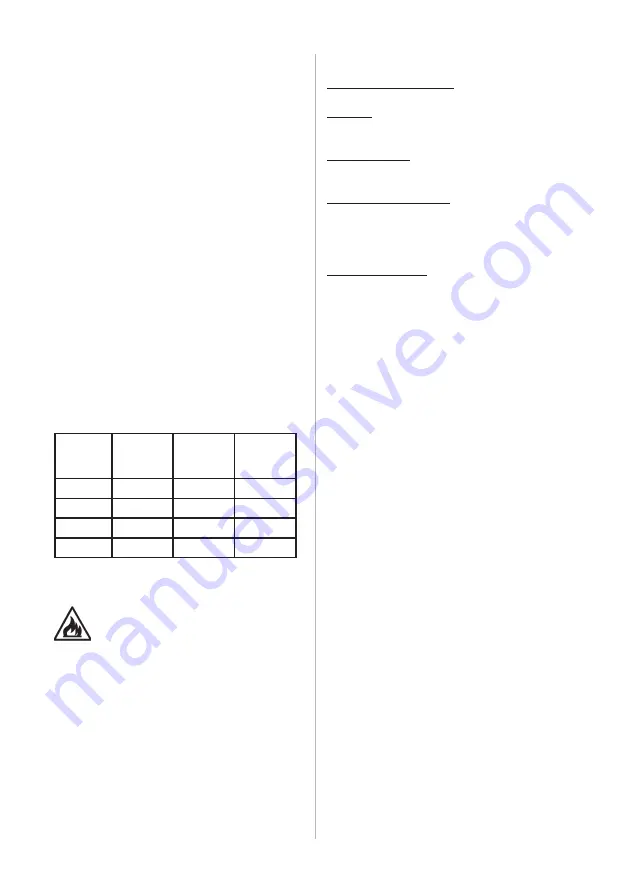

RECOMMENDED FIRE-

EXTINGUISHING DEVICES

For guidance on the most suitable type of ex-

tinguisher, refer to the table below:

Dry mate-

rials

Flam-

mable

liquids

Electrical

equip-

ment

Water

YES

NO

NO

Foam

YES

YES

NO

Powder

YES*

YES

YES

CO

2

YES*

YES

YES

YES* Use only if more appropriate extinguishers

are not at hand or when the fire is small.

WARNING

This table contains general instructions in-

tended to be used as guidelines for users.

Contact the manufacturer for details of the

applications of each type of extinguisher.

GLOSSARY

Air delivery regulator

. Union allowing regu-

lation of the air flow.

Beading

. Operation which takes place during

inflation and ensures perfect centring between

the bead and the rim edge.

Bead breaking

. Operation in which the bead

of the tyre is detached from the edge of the

rim.

Bead pressing gripper

. A tool intended for use

when mounting the top bead. It is fitted so that

it grips the shoulder of the rim and holds the tyre

top bead inside the drop centre. It is generally

used for mounting low profile tyres.

Tubeless Inflator.

An inflation system which

simplifies inflating tubeless tyres.

TROUBLE SHOOTING

t

urntable

will

not

turn

Power cord conductor shorting to ground.

• Check the wiring.

Motor shorted.

• Replace the motor.

• Replace motoinverter circuit board.

• Check pedal board micro.

Belt broken.

• Replace belt.

r

otation

Control

pedal

fails

to

return

to

Central

position

Control spring broken.

• Replace the control spring.

b

ead

breaking

unit

not

working

No vertical movement.

• Check for folded hoses.

• Check ascent and descent valve operation.

b

ead

breaking

unit

is

underpowered

,

does

not

break

the

bead

and

is

leaking

air

Carry out the checks in the previous point:

“Bead breaking unit not working”.

Cylinder gaskets worn.

• Replace gaskets.

• Replace bead breaker cylinder.

Summary of Contents for AQUILA RAPTOR

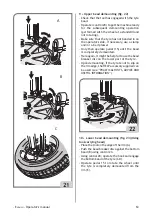

Page 34: ...34 Italiano Manuale d uso 35 a b c e d ...

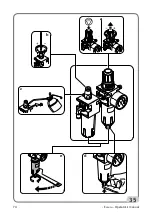

Page 39: ... Italiano Manuale d uso 39 4 104805A ...

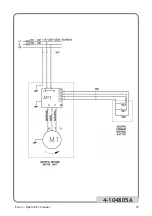

Page 40: ...40 Italiano Manuale d uso 4 108818 ...

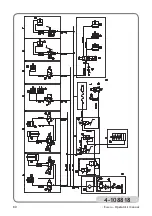

Page 41: ...41 ...

Page 42: ...42 ...

Page 74: ...74 English Operator s manual 35 a b c e d ...

Page 79: ... English Operator s manual 79 4 104805A ...

Page 80: ...80 English Operator s manual 4 108818 ...

Page 81: ...81 ...

Page 82: ...82 ...

Page 114: ...114 Français Manuel d utilisation 35 a b c e d ...

Page 119: ... Français Manuel d utilisation 119 4 104805A ...

Page 120: ...120 Français Manuel d utilisation 4 108818 ...

Page 121: ...121 ...

Page 122: ...122 ...

Page 154: ...136 Deutsch Betriebsanleitung 35 a b c e d ...

Page 159: ... Deutsch Betriebsanleitung 123 4 104805A ...

Page 160: ...134 Deutsch Betriebsanleitung 4 108818 ...

Page 161: ......

Page 162: ...162 ...

Page 194: ...176 Español Manual de uso 35 a b c e d ...

Page 199: ... Español Manual de uso 199 4 104805A ...

Page 200: ...174 Español Manual de uso 4 108818 ...

Page 204: ...204 ...

Page 205: ...205 ...