2-7

Standard specifications

2Robot arm

2 Robot arm

2.1 Standard specifications

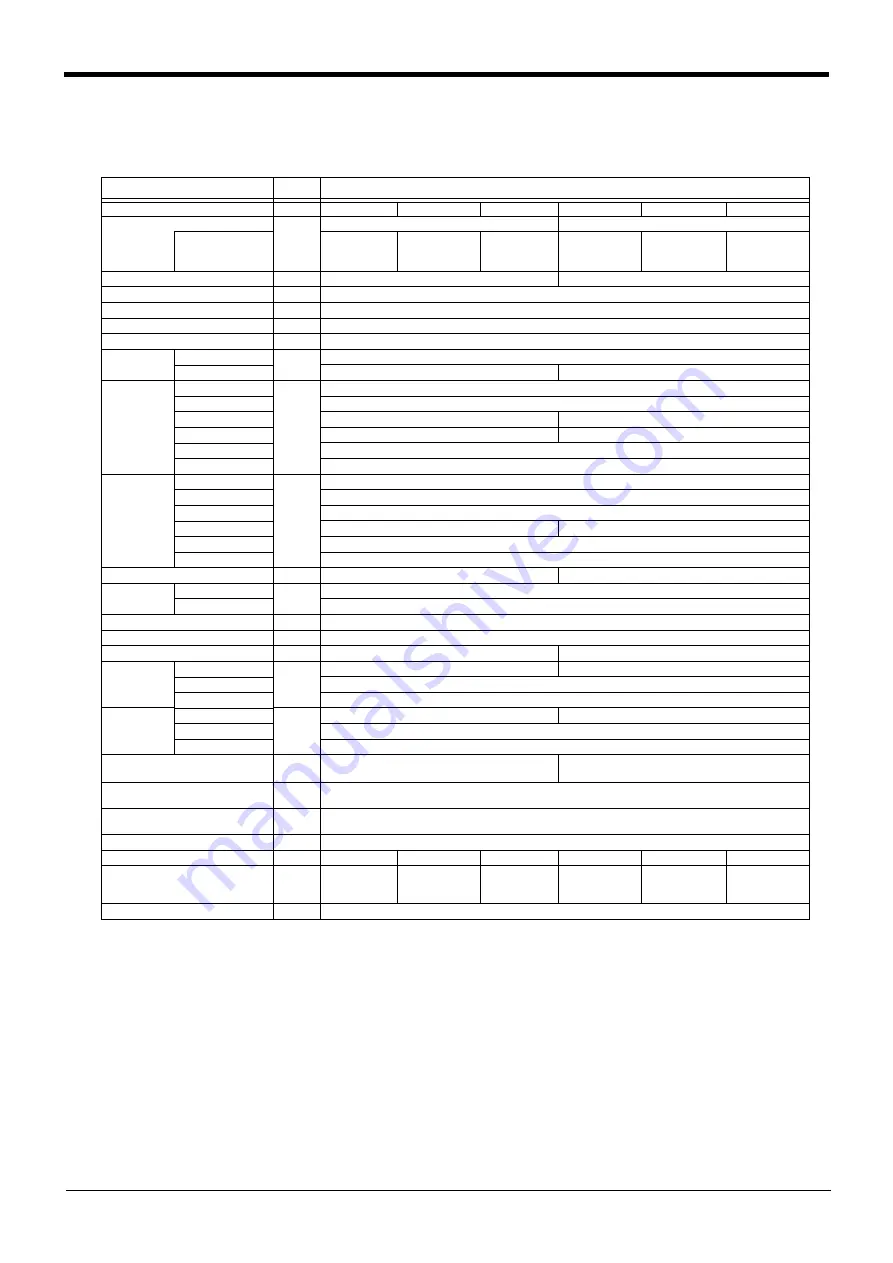

Table 2-1 : Standard specifications of robot

Item

Unit

Specifications

Type

RV-3SQ

RV-3SQC

RV-3Q-SM

RV-3SQJ

RV-3SQJC

RV-3SQJ-SM

Type of robot

6-axis

5-axis

Environment

Standard

(oil mist)

Clean

With the con

-

troller protec

-

tion box

Standard

(oil mist)

Clean

With the con

-

troller protec

-

tion box

Degree of freedom

6

5

Installation posture

On floor, hanging,(against wall

Note1)

)

Note1) When used by mounting on the wall, a special specification that limits the operating range of the J1 axis will be used.

Please give an order separately.

Structure

Vertical, multiple-joint type

Drive system

AC servo motor (J1 to J3:and J5: with brake)

Position detection method

Absolute encoder

Arm length Upper arm

mm

245

Fore arm

270

300

Operating

range

Waist (J1)

Note1)

Degree

340 (-170 to +170)

Shoulder (J2)

225 (-90 to +135)

Elbow (J3)

191 (-20 to +171)

237 (-100 to +137)

Wrist twist (J4)

320 (-160 to +160)

-

Wrist pitch (J5)

240 (-120 to +120)

Wrist roll (J6)

720 (-360 to +360)

Speed of

motion

Waist (J1)

Degree/

s

250

Shoulder (J2)

187

Elbow (J3)

250

Wrist twist (J4)

412

-

Wrist pitch (J5)

412

Wrist roll (J6)

660

Maximum resultant velocity

Note2)

Note2) This is the value on the mechanical interface surface when all axes are combined.

mm/sec

5,500

5,300

Load

Maximum

Note3)

Note3) The maximum load capacity is the mass with the mechanical interface posture facing down word at the ±10°limit.

kg

(N)

3.5 (34.3)

Rating

3 (29.4)

Pose repeatability

Note4)

Note4) The pose repeatability details are given in

Page 10, "2.2.1 Pose repeatability"

mm

±0.02

Ambient temperature

℃

0 to 40

Mass

kg

37

33

Allowable

moment load

Wrist twist (J4)

N ・ m

5.83

-

Wrist pitch (J5)

5.83

Wrist roll (J6)

3.9

Allowable

inertia

Wrist twist (J4)

kg ・ m

2

0.137

-

Wrist pitch (J5)

0.137

Wrist roll (J6)

0.047

Note5)

Note5) When the optimum acceleration/deceleration mode is in effect, up to twice the specification value indicated here can

be set.

Arm reachable radius front p-axis

center point

mm

642

641

Tool wiring

Note6)

Note6) The pneumatic hand interface (option) is required when the tool (hand) output is used.

Hand input 8 point, hand output 8 point, eight spare wires

(AWG#24(0.2mm

2

) with shielded)

Tool pneumatic pipes

Primary side: Φ6×2 (Base to fore arm section)

Secondary side: Φ4 ×8 (Optional)

Supply pressure

MPa

0.5±10%

Protection specification

Note7)

Note7) The protection specification details are given in

Page 13, "2.2.5 Protection specifications"

IP65 (all axes)

-

IP65 (all axes)

IP65 (all axes)

-

IP65 (all axes)

Degree of cleanliness

Note8)

Note8) The clean specification details are given in

Page 15, "2.2.6 Clean specifications"

. A down flow(0.3m/s or more) in the

clean room is the necessary conditions for the cleanliness.

-

10(0.3μm)

Internal suction

requirement

-

-

10(0.3μm)

Internal suction

requirement

-

Painting color

Light gray (Equivalent to Munsell: 0.08GY7.64/0.81)

Summary of Contents for MELFA CR1QA-700

Page 2: ......

Page 118: ......

Page 119: ......

Page 120: ......

Page 121: ......

Page 122: ......

Page 123: ......

Page 124: ......

Page 125: ......

Page 126: ......

Page 127: ......

Page 128: ......

Page 129: ......

Page 130: ......

Page 131: ......

Page 132: ......

Page 133: ......

Page 134: ......

Page 135: ......

Page 136: ......

Page 137: ......

Page 138: ......

Page 139: ......

Page 140: ......

Page 141: ......

Page 142: ......

Page 143: ......

Page 144: ......

Page 145: ......