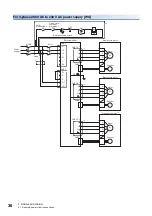

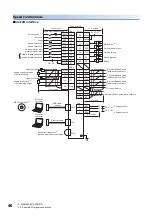

3 SIGNALS AND WIRING

3.1 Example power circuit connections

35

3

*1 P3 and P4 are connected from the factory. If using a power factor improving DC reactor, remove the short-circuit bar between P3 and

P4, then connect the power factor improving DC reactor. Additionally, the power factor improving DC reactor and a power factor

improving AC reactor cannot be used together.

Page 209 Power factor improving DC reactor

*2 Connect P+ and D terminals. P+ and D are connected from the factory. If using a regenerative option, refer to the following.

*3 Option cables are recommended for servo motor power cables and encoder cables. For selecting cables, refer to "Cable/connector sets"

in the following manual.

Rotary Servo Motor User's Manual (HK series)

*4 If ALM (Malfunction) output is disabled with a servo parameter, configure a power circuit which switches off a magnetic contactor after

detection of an alarm occurrence on the controller side.

*5 For connecting servo motor power wires, refer to "CONNECTION OF SERVO AMPLIFIER AND ROTARY SERVO MOTOR" in the

following manual.

Rotary Servo Motor User's Manual (HK series)

*6 Use the magnetic contactor with an operation delay time (interval between current being applied to the coil until closure of contacts) of

80 ms or less. The bus voltage may drop depending on the main circuit power supply voltage and operation pattern, causing a dynamic

brake deceleration during a forced stop deceleration. If dynamic brake deceleration is not required, delay the time to turn off the

magnetic contactor.

*7 If wires used for L11 and L21 are thinner than wires used for L1, L2, and L3, use a molded-case circuit breaker.

Page 199 Molded-case circuit breakers, fuses, magnetic contactors

*8 Connecting the servo motor for an incorrect axis to U, V, W, or CN2 of the servo amplifier may cause a malfunction.

*9 For 1-phase 200 V AC to 240 V AC power supply, connect the power supply to L1 and L3. Leave L2 open.

*10 If operating the on switch and off switch of the main circuit power supply with a DC power supply, do not share the 24 V DC power

supply for interface with the magnetic contactor. Use the power supply designed exclusively for the magnetic contactor. Refer to the

following for the magnetic contactors that can be used.

Page 204 Driving on/off of main circuit power supply with DC power supply [G] [A]

Operating the on switch and off switch with the DC power supply meets IEC/EN 60204-1 requirements. Also, change the configuration of

the part inside the dotted line as follows.

*11 When connecting a linear servo motor that has a thermal protector, add a contact that interlocks with the thermal protector output of the

linear servo motor.

*12 For MR-J5-500_ and MR-J5-700_ servo amplifiers, the CNP1 connector is divided into two: CNP1A connector (L1/L2/L3) and CNP1B

connector (N1/P3/P4).

MC

MC

SK

RA1

RA2

24 V DC

Malfunction

OFF

ON

Emergency stop switch

Servo motor

overheat protection

Summary of Contents for Melservo-J5 MR-J5 Series

Page 2: ......

Page 441: ...12 USING A FULLY CLOSED LOOP SYSTEM 12 7 Absolute position detection system 439 12 MEMO ...

Page 445: ......