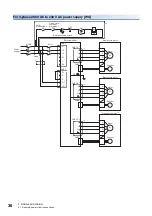

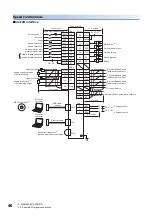

3 SIGNALS AND WIRING

3.2 Example I/O signal connections

45

3

■

Source I/O interface

Precautions

• For notes, refer to the notes in the following section.

47

DOCOM

48

ALM

23

ZSP

25

TLC

24

INP

4

LA

5

LAR

6

LB

7

LBR

34

LG

33

OP

SD

CN3

*7

LG

DICOM

41

20

46

49

10

11

35

9

3

36

CLEARCOM

12

15

16

13

14

11

CLEAR

RDYCOM

READY

PULSE F+

PULSE F-

PG0

PG0 COM

PULSE R+

PULSE R-

18

10

17

9

DOCOM

CR

RD

PP

PG

NP

NG

LZ

LZR

8

*10

CN3

*7

SD

42

15

19

17

18

43

44

21

EM2

SON

RES

PC

TL

LSP

LSN

DICOM

CN3

*7

CN3

*7

*13

1

27

SD

P15R

TLA

LG

28

MO1

MO2

3

LG

1

2

DC ± 10 V

DC ± 10 V

CN6

*2

RA2

RA3

RA4

RA1

*5

RD75D/LD75D/QD75D

*15

CN5

+

CN1

CN8

*1

MR Configurator2

*9

Servo amplifier

10 m or less

24 V DC

*4*14

Positioning module

24 V DC

*4*14

Malfunction

*6

Zero speed detection

Limiting torque

In-position

Encoder A-phase pulse

(differential line driver)

Encoder B-phase pulse

(differential line driver)

Plate

Control common

10 m or less

*8

Control common

Encoder Z-phase pulse (open collector)

Plate

2 m or less

Upper limit setting

Analog torque limit

+10 V/maximum torque

Plate

2 m or less

10 m or less

Main circuit power supply

*12

Forced stop 2

*3*5

Servo-on

Reset

Proportional control

Analog monitor 1

External torque limit selection

Forward rotation stroke end

Analog monitor 2

2 m or less

Reverse rotation stroke end

24 V DC

*4*14

USB cable

Short-circuit connector

*11

(Packed with the servo amplifier)

Personal

computer

Personal

computer

Ethernet cable

(option)

Summary of Contents for Melservo-J5 MR-J5 Series

Page 2: ......

Page 441: ...12 USING A FULLY CLOSED LOOP SYSTEM 12 7 Absolute position detection system 439 12 MEMO ...

Page 445: ......