Interleaf EP5000/EP4000 GENERAL, MECHANICAL/ELECTRICAL

97.04.01

M-51

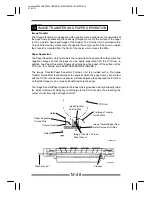

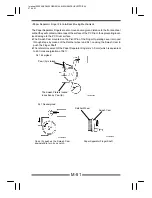

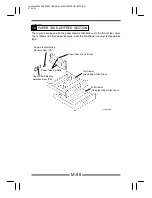

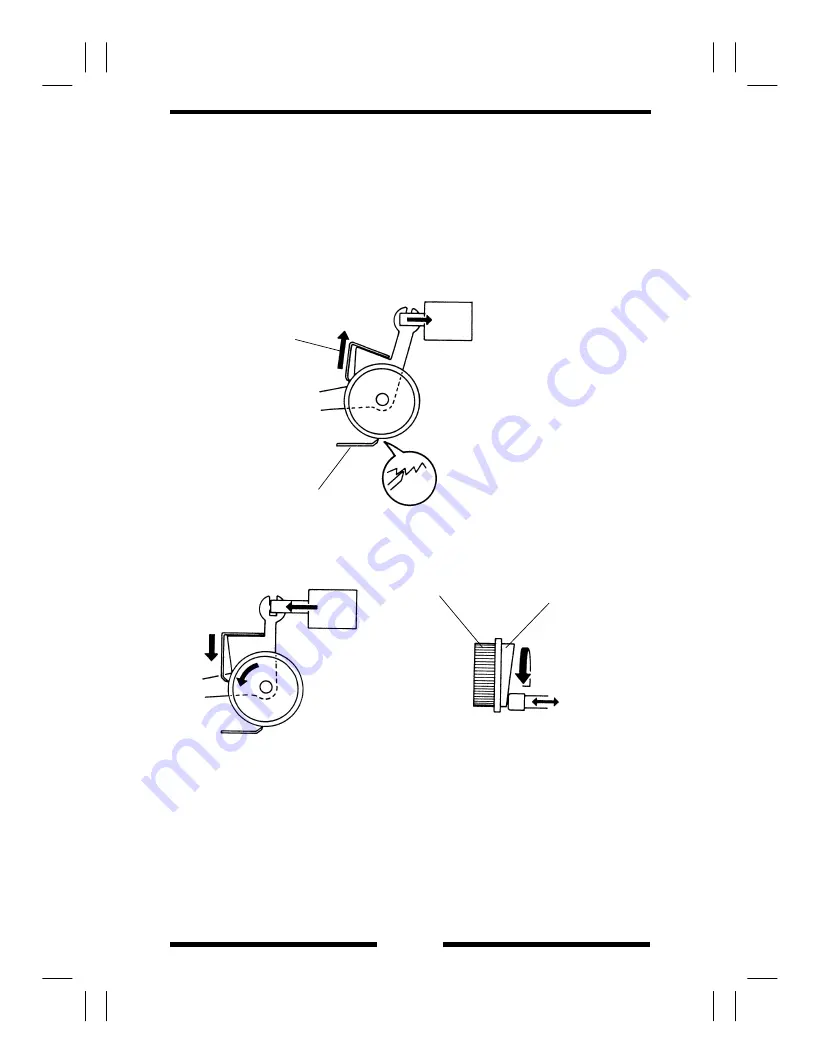

<Paper Separator Finger Front-to-Back Moving Mechanism>

The Paper Separator Fingers are also moved over a given distance to the front and rear

so that they will contact wider areas of the surface of the PC Drum, thus preventing local-

ized damage to the PC Drum surface.

D

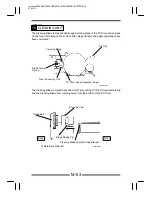

The Swash Cam mounted on the Pivot Pin of the Finger Operating Lever is moved

through steps by means of the Ratchet wheel and SL1, causing the Swash Cam to

push the Finger Shaft.

D

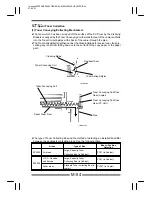

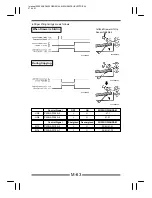

The lateral movement of the Paper Separator Fingers is 3.5 mm (which is equivalent

to 60 times energization of SL1).

SL 1 Energized

Pawl (A) is raised.

The Swash Plate is locked

in position by Pawl (B).

1136M065AA

SL 1 Deenergized

Pawl (A) pushes the Swash Cam

downward to turn it one notch.

Ratchet Wheel

Swash Cam

Paper Separator Finger Shaft

1136M067AA

1136M066AA