Interleaf EP5000/EP4000 GENERAL, MECHANICAL/ELECTRICAL

97.04.01

M-2

1156SBM0200A

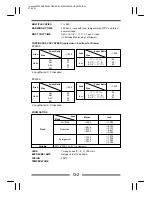

COPY PROCESS

2

1. PC DRUM

2. DRUM CHARGING

3. IMAGE ERASE

4. EXPOSURE

5. DEVELOPING

6. PAPER FEEDING

7. IMAGE TRANSFER

8. PAPER SEPARATION

9. CLEANING

10. MAIN ERASE

11. TRANSPORT

12. FUSING

13. PAPER EXIT

1

5

9

10

2

3

4

6

13

12

11

8

7

MULTI BYPASS

TABLE

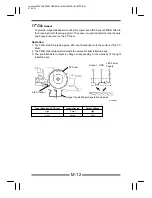

1. PC Drum

The PC Drum is an aluminum cylinder coated with a photosensitive semiconductor.

It is used as the medium on which a visible developed image of the original is formed.

(For more details, see “8. PC DRUM”.)

2. Drum Charging

The PC Drum Charge Corona Unit is equipped with a Comb Electrode and a Scorotron Grid to

deposit a uniform negative charge across the entire surface of the PC Drum.

(For more details, see “9. DRUM CHARGING”.)

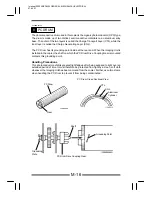

3. Image Erase

Any areas of charge which are not to be developed are neutralized by lighting up LEDs.

(For more details, see “10. IMAGE ERASE LAMP”.)

4. Exposure

Light from the Exposure Lamp reflected off the original is guided to the surface of the PC

Drum and reduces the level of the negative charges, thereby forming an electrostatic latent

image.

(For more details, see “11. OPTICAL SECTION”.)

5. Developing

Toner positively charged in the Developer Mixing Chamber is attracted onto the electrostatic

latent image changing it to a visible, developed image. A DC negative bias voltage is applied

to the Sleeve/Magnet Roller to prevent toner from being attracted onto those areas of the PC

Drum which correspond to the background areas of the original.

(For more details, see “13. DEVELOPMENT”.)