Interleaf EP5000/EP4000 GENERAL, MECHANICAL/ELECTRICAL

97.04.01

M-14

1156SBM0703A

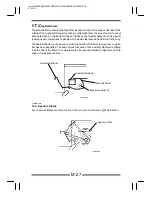

7-3. Details of Image Stabilization Controls

À

AIDC Sensor adjustment

Á

Grid voltage and T/C correction

Â

Optimum Exposure Lamp voltage

correction

Ã

AE Sensor gain adjustment

D

The following is the details of each image stabilization control.

À

-1 AIDC Sensor coarse adjustment

This adjustment represents a coarse adjustment of the AIDC Sensor when the

ordinary control of only the LED current cannot cover part-to-part variations in the

AIDC Sensor (installation, circuit, deterioration, etc.). The surface of the PC Drum

whose charges have been neutralized is exposed to light from the LED. The output

current from the AIDC Sensor goes through the load resistance selected by a 4-bit

analog switch and the 4-bit analog switch selects the load resistance so that the

resultant voltage becomes 1V or less.

À

-2 AIDC Sensor fine adjustment

If the AIDC Sensor is dirty with toner, it results in an error being produced in the

sensor output voltage value, providing a false reference value. The surface of the

PC Drum which has been erased is exposed to light from the LED. The LED current

value is varied through pulse width control so that the output voltage from the AIDC

Sensor becomes 1V.

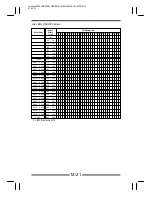

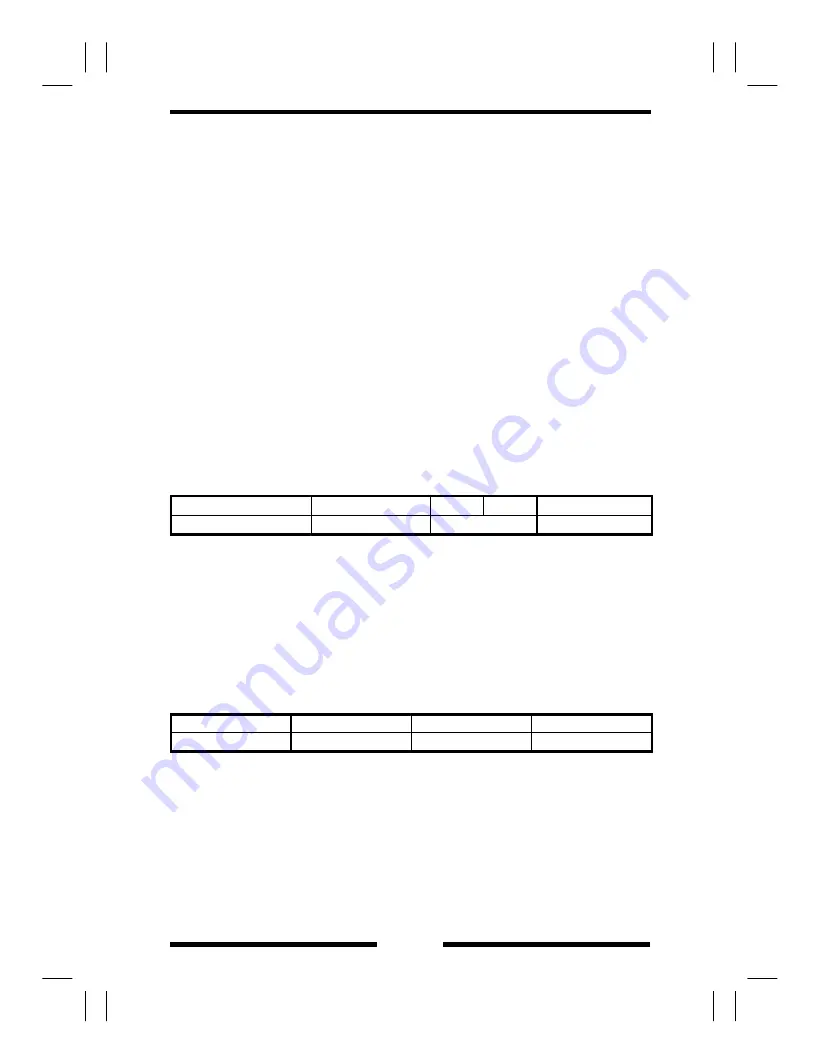

Controlled Part

Control Signal

ON

OFF

WIRING DIAGRAM

AIDC Sensor

PJ11A-7A

Pulse output

1-I

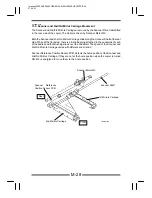

Á

Grid voltage and T/C correction

The Image Erase Lamp produces a solid-black pattern on the surface of the PC

Drum and the AIDC Sensor reads the pattern. The grid voltage is then varied so

that the output from the AIDC Sensor remains at a given level or higher, which en-

sures that the toner-to-carrier ratio on the surface of the PC Drum becomes

constant.

If an even greater solid-black density is required when the upper control limit of the

grid voltage has already been reached, the target control value of T/C is raised in

0.5% steps up to 7%, thus terminating the adjustment sequence.

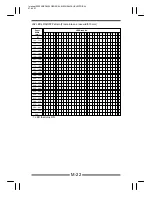

Control Value

1 Step

Initial Value

Grid Voltage

550 to 790V

30V

550V