Technical specifications

246

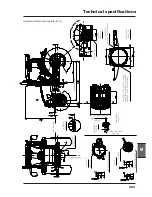

4WD front axle

Front axle in spheroidal cast iron pivoting around two

central supports.

Electro-hydraulic front drive engagement by means of

hydraulic clutch.

Spring-On/Pressure-Off type.

Propeller shaft without universal couplings installed along

the longitudinal axis of the tractor.

Transmission through central differential and epicyclic

final drives in the wheel hubs.

Max. steering angle ....................................................55°

Front axle with oil-cooled front brakes.

The front brakes

are the oil-cooled multi-disc type mounted on the live

axles of the front differential: 4 discs (2 for each live axle).

Electro-hydraulically controlled “Twin-Lock” differential

lock

mounted as standard supply. Engagement occurs at

the same time the rear differential is engaged. The diffe-

rential lock is disengaged by means of the brake pedals.

Interflange: ...............................................................1887

Distance between kingpins ...............................1530mm

Reduction ratios

Bevel gear pair: .............................................8/31=3.875

Epicyclic final drives: ...............................15/15+63=5.2

Total reduction ratio: ...............................................20.15

Transmission ratio between front and rear

axles ......................................................................1.3882

Track width adjustment

To adjust the track width of the front axle and rear axle,

see the tables in the “Operation” chapter.

Steering components

Power steering

Power steering system controlled by the steering wheel.

Telescopic steering wheel adjustable in height and tilt.

Gear pump with a delivery rate of 31 l/min at a 2200 RPM

engine rate (see “Description of the Hydraulic Circuit”).

Paper filter on the delivery side.

Balanced, double-acting steering cylinder mounted on

the axle casing.

Max. working pressure in power steering

system .........................................................150 +/- 5 bar

Max. steering angle without brakes, 4WD: .......5200mm

Summary of Contents for X60 Series

Page 39: ...39 Controls Cab 3 Section 3 Controls Cab...

Page 61: ...61 Instruments and Programming 4 Section 4 Instruments and Programming...

Page 90: ...90 Instruments and Programming This page has been left blank intentionally...

Page 91: ...91 Operation 5 Section 5 Operation...

Page 151: ...149 Tyres Wheels Ballasting 6 Section 6 Tyres Wheels Ballasting...

Page 168: ...166 Tyres Wheels Ballasting This page has been left blank intentionally...

Page 169: ...167 Maintenance 7 Section 7 Maintenance...

Page 229: ...Electrical system 227 8 Section 8 Electrical system...

Page 242: ...Electrical system 240 Page left intentionally blankf...

Page 256: ...Technical specifications 254 This page has been left blank intentionally...

Page 262: ...260 Alphabetical index...