213

Maintenance

7

9

1

2

6

5

4

3

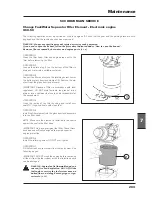

1000 HOUR MAIN SERVICE

Engine air filter service

OPERATION 1

Pull out the yellow tab (1), turn the cover (2) anti-clockwise

and remove.

OPERATION 2

Pull out the primary (outer) filter element (3).

OPERATION 3

Pull out the secondary (inner) filter element (4), if it has

to be changed.

IMPORTANT: DO NOT remove the secondary (inner) ele-

ment unless it has to be changed.

OPERATION 4

Clean the inside of the filter body (5).

IMPORTANT: Dispose of filters correctly in accordance

with local regulations. Be responsible for the environment.

OPERATION 5

Install a new secondary (inner) element (4), if necessary

or after the third cleaning of the primary filter (3). Apply

talcum powder or similar to the inner seal face before

installing the filter. Install with closed end outwards.

NOTE: NEVER use a petroleum base lubricant on the seal

area. Petroleum lubricant could "glue" the cover to the

element seal and damage the element.

CAUTION: If you need to open the bonnet, follow the procedure indicated under “How to open the bonnet”.

WARNING: Always use specific personal safety devices for each operation.

WARNING: Maintenance operations must be carried out with the engine off. Check that the gear and the par-

king brake are both engaged and that the ignition key has been removed.

WARNING: Beware of burns caused by hot tractor and engine parts.

[4.1.n]

WARNING: The internal filter element must not be

replaced. NEVER attempt to clean the internal safety

element.

IMPORTANT: A new rubber dust valve MUST be installed

every 1000 hours.

Summary of Contents for X60 Series

Page 39: ...39 Controls Cab 3 Section 3 Controls Cab...

Page 61: ...61 Instruments and Programming 4 Section 4 Instruments and Programming...

Page 90: ...90 Instruments and Programming This page has been left blank intentionally...

Page 91: ...91 Operation 5 Section 5 Operation...

Page 151: ...149 Tyres Wheels Ballasting 6 Section 6 Tyres Wheels Ballasting...

Page 168: ...166 Tyres Wheels Ballasting This page has been left blank intentionally...

Page 169: ...167 Maintenance 7 Section 7 Maintenance...

Page 229: ...Electrical system 227 8 Section 8 Electrical system...

Page 242: ...Electrical system 240 Page left intentionally blankf...

Page 256: ...Technical specifications 254 This page has been left blank intentionally...

Page 262: ...260 Alphabetical index...