77

1

1921 Slauson

A

ve. Santa Fe Springs, CA. 90670 (800) 227-41

16 F

AX (888) 771-7713

STEP 16 - FINISH WELDING LIFTGATE TO VEHICLE

METHOD 2 & METHOD 3 - WELD LIFTGATE TO BODY

NOTE:

Skip this step if using

METHOD 1

installation where mounting plates and

extension plate are preinstalled on vehicle.

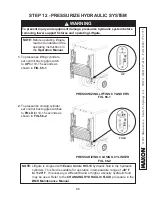

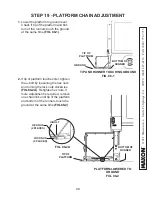

POSITIVE (+)

BATTERY POST

WARNING

!

To prevent accidental personal injury

and equipment damage, disconnect

(-) battery cable and (+) cable from

battery.

2.

Disconnect power to the pump by

disconnecting negative

(-)

and positive

(+)

cables from battery

(FIG. 77-1)

.

Reinstall nuts on negative

(-)

and posi-

tive

(+)

battery terminals.

NEGATIVE (-)

BATTERY CABLE

NEGATIVE (-)

BATTERY POST

NUT

POSITIVE (+)

BATTERY CABLE

DISCONNECTING BATTERY POWER

FIG. 77-1

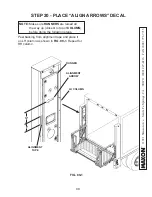

1.

Check operation of Liftgate before

fi

nal

welding. See

BMR-CS Operation Manual

.

Summary of Contents for BMR-CS

Page 103: ......