29

1

1921 Slauson

A

ve. Santa Fe Springs, CA. 90670 (800) 227-41

16 F

AX (888) 771-7713

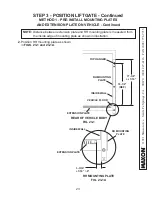

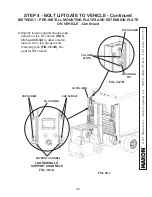

STEP 3 - POSITION LIFTGATE - Continued

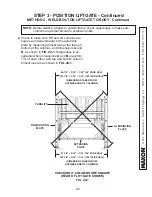

ALTERNATE

2” LG. X 3

PLACES

INBOARD & 2”

LG. X 3 PLACES

OUTBOARD OF

LH & RH

COLUMNS OR

MOUNTING

PLATES

WELDING LIFTGATE TO

VEHICLE

FIG. 29-1

1/4”

1/4”

TYPICAL

CLAMPS

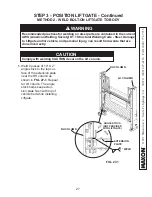

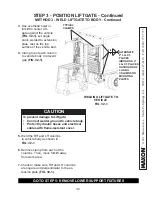

To prevent damage to Liftgate:

• Connect welder ground to vehicle body.

• Protect hydraulic hoses and electrical

cables with fl ame-resistant cover.

CAUTION

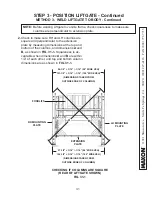

3.

Use overhead hoist or fork

lift to center Liftgate

against the vehicle

(FIG.

29-1)

. Let angle stock,

welded to extension plate,

rest on the top surface of

the vehicle bed.

4.

Clamp top of each column

to vehicle body to prevent

gap

(FIG. 29-1)

.

5.

Weld the RH and LH columns

to vehicle body as shown in

FIG. 29-1

.

6.

Remove clamp from each of

the columns. Then, move fork-

lift away from work area.

METHOD 2 - WELD BOLT-ON LIFTGATE TO BODY - Continued

GO TO STEP 5: REMOVE LOWER SUPPORT FIXTURES

7.

Check to make sure RH and LH columns

are square and perpendicular to the ex-

tension plate

(FIG. 27-1)

.

Summary of Contents for BMR-CS

Page 103: ......