79

1

1921 Slauson

A

ve. Santa Fe Springs, CA. 90670 (800) 227-41

16 F

AX (888) 771-7713

STEP 16 - FINISH WELDING LIFTGATE TO VEHICLE

METHOD 2 & METHOD 3 - WELD LIFTGATE TO BODY - Continued

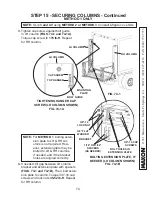

5.

Make sure platform is at ground

level to provide access to the

extension plate.

To prevent damage to Liftgate

components, welder ground

must be connected to Liftgate

extension plate.

CAUTION

NOTE:

After welding top of exten-

sion plate, if you see a gap

between bottom of extension

plate & vehicle body sill,

fi

ll the

gap. To

fi

ll the gap, use A-36

General Purpose steel and

the same welds shown in

FIG.

79-2

.

6.

Weld the top and bottom surfaces

of extension plate

(FIGS. 79-1 &

79-2)

to vehicle body sill.

7.

Weld entire length

(FIG. 79-2)

on the bottom of LH and RH end

blocks.

START AT CENTER.

ENDS MUST BE

WELDED. TYPICAL -

17 WELDS.

3/16”

WELDING TOP OF EXTENSION PLATE

FIG. 79-1

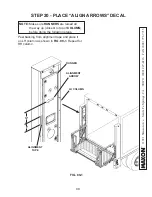

LH END

BLOCK

RH END

BLOCK

FULL LENGTH OF

END BLOCK

3/16”

3/16”

WELDING BOTTOM OF EXTENSION PLATE

FIG. 79-2

2-5

CENTER

START AT CENTER.

ENDS MUST BE

WELDED. TYPICAL -

17 WELDS.

2-5

CENTER

Summary of Contents for BMR-CS

Page 103: ......