www.maxcessintl.com

MAGPOWR Spyder-Plus-S1 Tension Control

MI 850A351 1 C

Page 3 of 68

COPYRIGHT

All of the information herein is the exclusive proprietary property of Maxcess International, and is

disclosed with the understanding that it will be retained in confidence and will neither be duplicated nor

copied in whole or in part nor be used for any purpose other than for which disclosed.

Copyright 2015, 2016, 2020 all rights reserved.

Periodically there will be updates to this manual. The latest version is available on our website or by

calling the number on the back page of this publication.

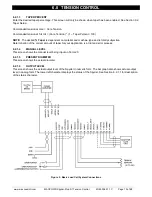

ABOUT THE SPYDER-PLUS-S1

The MAGPOWR Model Spyder-Plus-S1 (hereafter referred to as Spyder) is a microprocessor-based

control designed for precise closed loop control of either web tension, dancer position, or open loop

tension control proportional to a diameter input for unwinds and rewinds. The Spyder has a diameter input

to compensate for large roll builds in the dancer modes and provide for inertia compensation in

Load Cell

and

Dancer, Torque

modes.

The web tension control is capable of controlling web tension in unwind, rewind, or point-to-point

applications in any web press. The Spyder measures tension from one or more MAGPOWR load cells

and outputs a corrective analog signal to control a torque device. The tension setpoint for the Spyder is

set by an analog voltage signal or by a parameter from an Ethernet port. The Spyder provides an analog

input for Manual Level setpoint, control inputs for Run/Stop, Auto/Manual, Tension On/Off and E-Stop,

and a 0 1 mA or 0-10 VDC meter output proportional to measured tension. Inertia compensation during

stopping is available. Hold Level Output during Hold mode can be a fixed level, or vary with last running

output, or vary based on diameter and or tension.

The dancer control is capable of controlling a dancer in unwind or rewind applications in any dancer

system. The dancer control output can be connected to a torque device (brake or clutch), or a speed

device (motor). The Spyder measures the dancer position, using a MAGPOWR DFP potentiometer

connected to the dancer arm, and outputs a corrective analog signal to control a torque or speed device

that keeps the dancer position constant. The dancer setpoint for the Spyder is set by an analog voltage

signal or by a software setpoint which can be changed on the Spyder or from the Ethernet port. The

Spyder provides control inputs for Run/Stop, Tension On/Off, and E-Stop. The tension in the web is fixed

by the dancer loading. Additionally, load cells may be read while in Dancer mode and the 0-1 mA or 0-1

VDC meter output is proportional to measured tension. With

Diameter

selected in

Dancer

mode, the

diameter input is available to compensate for large roll builds. Inertia compensation during stopping is

available in Torque mode. In Torque mode, Hold Level Output during Hold mode can vary with last

running output, or vary based on diameter and or tension. In Speed mode, the output during Hold is

always zero.

The open loop tension control is capable of controlling the tension on an Unwind or Rewind based on an

analog diameter input including taper tension and inertia compensation during stopping. The tension

setpoint is set by an analog voltage signal or by a parameter from an Ethernet port. The control provides

an analog input for Manual Level setpoint, control inputs for Run/Stop, Auto/Manual, Tension On/Off and

E-Stop, and a 0-1 mA or 0-10 VDC meter output proportional to Diameter at Core divided by Present

Diameter to slow down Rewind motors to reduce clutch power dissipation.

The Spyder provides an Ethernet port for programming and data collection using either a web page or

Modbus/TCP.

Summary of Contents for MAGPOWR Spyder-Plus-S1

Page 2: ......