7.0 DANCER CONTROL

www.maxcessintl.com

MAGPOWR Spyder-Plus-S1 Tension Control

MI 850A351 1 C

Page 26 of 68

7.2.2.6

HOLD LEVEL CHANGE WITH

Allows the output during Hold to vary by last running Output, Diameter, Tension, or Diameter and Tension. Load

cells must be enabled to read tension. See section 9.6.14 to enter hold level multiplier when choice is Output. See

section 9.6.13 for calibrating Hold level when the choice is Diameter, Tension, or Diameter and Tension.

7.2.2.7

USE LOAD CELLS

Enables reading of the load cells while in Dancer mode. See Section 6.3 to calibrate load cells.

7.2.2.8

OUTPUT RANGE

Select the main output range. For a main output range of either 0-10 VDC or 4-20 mADC select NORMAL. For the

-10 to +10 VDC

range select

-10V to +10V

. The software is factory calibrated for the

0-10 VDC

and the

-10 to +10 VDC

output ranges. See Section 9.4 for recalibrating the output when using the 4-20 mADC range. See

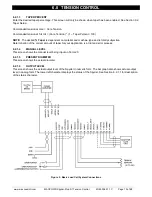

Figure 4 for jumper settings.

7.2.2.9

SETPOINT SOURCE

Select the source for the dancer setpoint. When set to ANALOG the Spyder will use the voltage on terminal 16 as

the dancer position setpoint. When set to ETHERNET the Spyder will use the software value of setpoint position.

This value may be changed either at the keypad, the web page, or by Modbus/TCP. Use the

Setpoint Position

screen in the

Operator Loop

to change the software setpoint.

7.2.2.10

DIGITAL INPUT ACTIVE LEVEL

The digital control inputs may be either

Active Low

or

Active High

. The software is factory configured for Active

Low inputs. See Section 5.2 and Figure 4.

7.2.2.11

INITIAL SCREEN

The first screen after power-up is the

Operator Loop

screen. This parameter allows the initial power-up screen to

be changed to either the

Position

screen, Section 7.2.1.1 or the

Output Level

screen, Section 7.2.1.3 or the

Diameter Display

screen.

7.2.2.12

NUMERIC UPDATE RATE

This parameter controls filtering for the numeric actual position and the actual output displays. Default values work

well in most applications.

7.2.2.13

BAR GRAPH UPDATE RATE

This parameter controls filtering for the bar graph actual position and the actual output displays. Default values

work well in most applications.

7.2.2.14

SCREEN CONTRAST

This screen allows adjustment of the screen contrast. See Section 10.1, General Problems, when screen shows no

characters.

7.3 DANCER INPUT SETUP (REQUIRED)

7.3.1

Setup DFP or DFP-2

7.3.1.1

DFP

Install the DFP sensor so that its keyway is pointing towards the top cover when the dancer is half way through its

travel. This is an approximate adjustment, and is intended to center the sensor position to allow maximum rotation

in both directions during operation.

7.3.1.2

DFP-2

To find the electrical center point of pot rotation, use a digital multimeter type ohm meter to measure from the white

wire (wiper), to the red or black wire. Turn the potentiometer shaft until the meter reads 500 ohm. Install the DFP-2

sensor so that at the 500 ohm meter reading, the dancer is halfway through its travel.

7.3.1.3

Check DFP or DFP-2 voltage

Verify the dancer voltage between Term. 38 and Term. 39 matches the voltage change with dancer movement as

shown in Figure 12. If the dancer voltage is opposite that shown in the figure, simply swap the wires on Term. 39

and Term. 26. This will reverse the dancer voltage change.

Summary of Contents for MAGPOWR Spyder-Plus-S1

Page 2: ......