5 - 51

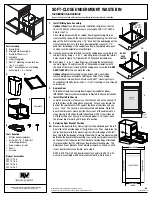

Air bleed plug

(3) Air-bleeding from clutch line

(MEC models only)

If there are air bubbles in the hydraulic clutch line,

the main clutch may not be released completely.

1. Stop engine and apply parking brake. Fill the

brake oil tank with new oil sufficiently.

For oil specification, see page 5-15.

2. Carry out air-bleeding work from clutch release

cylinder first and clutch master cylinder later.

3. Loosen the air-bleed plug and press and hold

the clutch pedal down slowly up to full stroke.

4. Fasten the plug slightly and then release the

clutch pedal. Repeat procedure 3~4 for several

times.

5. If there is no bubbles coming out through the air

bleed plug, check if the main clutch is completely

disengaged. Check the tightening torque of the

air-bleed plug.

(2) Air-bleeding from brake lines

1. As the brake system of this tractor is separated

into left and right brake, the air bleeding must be

carried out separately.

2. Stop engine and apply parking brake. Open the

bonnet and fill the brake oil tank with new oil

sufficiently.

For oil specification, see page 5-15.

3. Release the left/right connecting pin of the brake

pedals.

4. Loosen the air-bleed plug, and press and hold a

brake pedal down slowly up to full stroke.

5. Fasten the plug slightly, and then release the

brake pedal. Repeat procedure 4~5 for several

times.

6. Check the brake oil level frequently during the

air bleeding work.

7. If there is no bubbles coming out through the air

bleed plug, check if the brake pedal pressure

and equalization is normal. Check the tightening

torque of the air-bleed plug.

Air bleed plug

Clutch release cylinder

Brake oil tank

Air bleed plug

Clutch master

cylinder

Brake oil tank

Summary of Contents for XP8084

Page 1: ...LS TRACTOR OPERATOR S MANUAL XP8084 XP8094 XP8101 ...

Page 2: ......

Page 4: ......

Page 12: ......

Page 70: ......

Page 80: ...3 10 SCR inducement strategy Low DEF level ...

Page 81: ...3 11 SCR inducement strategy poor DEF quality ...

Page 82: ...3 12 SCR inducement strategy SCR System tampering detection ...

Page 188: ......

Page 261: ...5 73 Attachment ...

Page 262: ......

Page 280: ......

Page 282: ...8 2 2 Roll bar type Unit mm When applying front tire 12 4 24 8PR rear tire 16 9 34 8PR ...

Page 287: ......

Page 288: ......