Commissioning

Positioning mode

Functions available

5

61

SW-HB 13.0002-EN EN 3.0

Note!

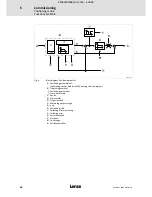

Unlike many competitive products, the servo positioning controller

re-calculates the complete traversing process in every control cycle. With this

concept, positioning processes can be modified or cancelled any time, even

during traversing.

This is made possible by the high performance of the Motion Control DSP used

in the 931E servo positioning controller.

The powerful positioning control of the 931E includes many parameters and position sets.

Up to 64 position sets can be saved in the non-volatile memory of the 931E and be

approached via the trajectory generator.

Each of the 64 position sets includes a separate target position. The other parameters of

the 64 position sets are equally divided into 4 groups. For each of the 4 groups, you can set

the following parameters:

ƒ

Acceleration

ƒ

Traversing speed

ƒ

Type of acceleration:

Acceleration with jerk limitation or time optimal (constant acceleration)

ƒ

Relative or absolute positioning

ƒ

Waiting until end of current positioning or deletion of current positioning

ƒ

Start delay

In addition, there are position sets for positioning via the CAN bus (DSP402) and homing.

The positioning control supports point-to-point motion sequences with final speed = zero

(standstill at target position). The cancellation of positioning processes during traversing

and direct approaching of the next position selected is also supported.

The groups and positions are selected via the digital inputs (

72). As an alternative, the

groups and positions can also be selected via the RS232 interface.

For homing or positioning via CAN (DS402), the corresponding position data records will

be directly assigned to the trajectory generator.

efesotomasyon.com - Lenze