177

8

Options

Flu

e

gas te

m

pe

ra

tu

re

O

ut

side

t

em

p

er

at

ur

e/

setpoi

nt shift

Boile

r water

tem

per

atur

e/

Deactivation of po

w

er

contr

o

l uni

t

Steam

p

re

ssur

e

actual valu

e

Ma

nua

l r

e

gu

lar

fir

ing

r

ate inp

u

t

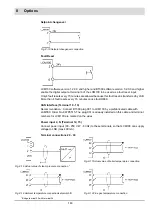

TPS (Three-Point-Step)

Potentiometer

0 ... 10 V

4 ... 20 mA

R

= 2.2 k

- 22 k

LED1

= Error

LED2

= CAN data traffic

LED3

= Power ON

GND

24

V

Oil fu

el meter

Gas

fuel meter

Setpoin

t cha

nge

over

Fa

ult

r

es

et

(L

C

M

v

1.

2.0

.0

a

nd

h

ighe

r)

4 ... 20 mA

mo

n

itor

o

utpu

t (

+

)

4....

20

mA

m

onitor output

(-)

CAN Rx

CA

N

Tx

V5

VSS

N

L

C

A

N interfac

e

fr

om BT3

00

P

ower supply

Summary of Contents for BT300 BurnerTronic

Page 2: ......

Page 25: ...24 3 Product Description Fig 3 9 Temperature derating BT300 for operation 2000 m NHN...

Page 49: ...48 4 Design and Functions Fig 4 20 Oil with pilot burner BT300...

Page 50: ...49 4 Design and Functions Fig 4 21 Oil without pilot burner BT300...

Page 51: ...50 4 Design and Functions Fig 4 22 Gas with pilot burner and leakage test BT300...

Page 52: ...51 4 Design and Functions Fig 4 23 Gas without pilot burner and leakage test BT300...

Page 53: ...52 4 Design and Functions Fig 4 24 Oil without pilot burner BT335...

Page 54: ...53 4 Design and Functions Fig 4 25 Gas without pilot burner and leakage test BT335...

Page 59: ...58 4 Design and Functions Fig 4 28 Leakage test process diagram...

Page 98: ...97 6 Operating Control and Displays...

Page 99: ...98 6 Operating Control and Displays...

Page 103: ...102 6 Operating Control and Displays...

Page 105: ...104 6 Operating Control and Displays...

Page 106: ...105 6 Operating Control and Displays...

Page 107: ...106 6 Operating Control and Displays...

Page 109: ...108 6 Operating Control and Displays...

Page 126: ...125 6 Operating Control and Displays 6 3 4 2 Curve Table Fig 6 37 Curve table window...

Page 246: ...242 10 EU Declaration of Conformity 10 EU Declaration of Conformity...

Page 247: ...243 10 EU Declaration of Conformity...