172

8

Options

•

P share, I share, D share are added up and serve as adjustments to the firing rate default

of the fuel/air ratio control.

•

As long as the actual value is below setpoint, P term and I term are positive, that is to say

both of these terms will increase the firing rate default.

•

In such a case only D term has a negative value (assuming that boiler temperature is ris-

ing). Use D term carefully because it leads to a higher burden for the actuating elements.

•

In order to avoid excessive overshoot during burner start-up adjust parameters to achieve

a suitably large D term.

•

If despite a large setpoint deviation the burner is not run at full or base firing rate you

should increase the P term.

•

The longer you select the adjustment time the calmer the fuel/air ratio control. However,

this also increases the actual values’ deviation from setpoint value and leads to slower ad-

justment.

Adjustment of the values according to the controlled system is highly recommended.

8.1.11

Aides for Setting

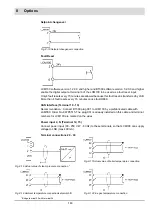

Fig. 8-6 Controller operation with P-term too high

Hot Water Installations

Steam Boiler Installations

P term

120

280

600

I term

60

360

300

D term

20

50

25

Adjustment time

15

2

20

Characteristic

Control Process

Control Mode

Start-up Procedure

P term higher

decrease of

attenuation

stronger reaction with

overshoot

faster start-up with

overshoot

P term smaller

increase of

attenuation

less reaction, less ten-

dency to oscillate

slower startup

Characteristic

Control Process

Control Mode

Start-up Procedure

I term higher

decrease of atten-

uation

stronger reaction with

tendency to oscillate

faster start-up with ten-

dency to oscillate

I term smaller

increase of attenu-

ation

less reaction, less ten-

dency to oscillate

slower start-up

Summary of Contents for BT300 BurnerTronic

Page 2: ......

Page 25: ...24 3 Product Description Fig 3 9 Temperature derating BT300 for operation 2000 m NHN...

Page 49: ...48 4 Design and Functions Fig 4 20 Oil with pilot burner BT300...

Page 50: ...49 4 Design and Functions Fig 4 21 Oil without pilot burner BT300...

Page 51: ...50 4 Design and Functions Fig 4 22 Gas with pilot burner and leakage test BT300...

Page 52: ...51 4 Design and Functions Fig 4 23 Gas without pilot burner and leakage test BT300...

Page 53: ...52 4 Design and Functions Fig 4 24 Oil without pilot burner BT335...

Page 54: ...53 4 Design and Functions Fig 4 25 Gas without pilot burner and leakage test BT335...

Page 59: ...58 4 Design and Functions Fig 4 28 Leakage test process diagram...

Page 98: ...97 6 Operating Control and Displays...

Page 99: ...98 6 Operating Control and Displays...

Page 103: ...102 6 Operating Control and Displays...

Page 105: ...104 6 Operating Control and Displays...

Page 106: ...105 6 Operating Control and Displays...

Page 107: ...106 6 Operating Control and Displays...

Page 109: ...108 6 Operating Control and Displays...

Page 126: ...125 6 Operating Control and Displays 6 3 4 2 Curve Table Fig 6 37 Curve table window...

Page 246: ...242 10 EU Declaration of Conformity 10 EU Declaration of Conformity...

Page 247: ...243 10 EU Declaration of Conformity...