12

EN

Torpedo

The mechanism in the rear wheel axle allows braking using pedals. In order to stop the bicycle, it is enough to rotate the pedals in the opposite direction. This type of

brake may be serviced and repaired only by an authorised servicing station.

Disc brakes

In this system, disc brakes are installed on axis of axles of both wheels. By pulling on the braking lever (so called handle) installed on the handlebars, the cyclist effects

compression of pistons which cause friction to the disc though braking pads. Adjustment and maintenance of disc brakes requires knowledge, skills and specialist tools.

These actions should be performed by an authorised service station. The user can replace braking pads on their own. In order to do this, remove the wheel, remove pins

or springs fixing the pads, remove worn pads, install new pads and proceed with the same operations, performed in reverse. The model of the pads must be identical

with the ones in purchased bicycle. Do not press brake levers during braking pads replacement.

Maintaining cleanliness of braking discs significantly improves efficiency of disc brakes and riding safety.

Rim brakes (V-brake, U-brake)

In this system, arms of the brake press the pads to the wheel rim. Distance between the pads and the rim is adjusted using special screws on the arms of brakes or by

shortening-lengthening the brake line. The brake line connects the handle on the handlebars with the arms, to which it is connected using a screw (5-8 Nm). Brake lines

must be replaced at least once a year or every time where notches and breaks appear on their surface. Brake pads are screwed to arms (6-9 Nm) or slipped into special

guide. In order to replace the pads, they must be screwed off the arms or slipped out of the guides, after pulling the pins out. Installing the brake pads requires screwing

them to the arm after setting them at an appropriate height or slipping into the guides and putting the pins back on. Wear of brake pads is easy to evaluate thanks

to special grooves placed on them. If the surface of the pad was worn to the point where the grooves disappeared completely – the pad must be replaced. As pads

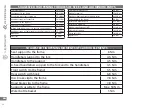

gradually wear out, the brake lines must be pulled up. Proper adjustment of pads – providing the most effective braking: pads set almost parallel to the rim, however,

in such a way that the back of the pad was ca. 2 mm further away from the rim than the front of the pad. Fig. 25. Please pay attention that the pad does not touch the

tyre during braking and was pressed to the rim along its entire surface. If the brake arms do not return on their own, clean and grease fixing points to the fork or to the

frame, or replace lines or shields. The brake handle should remain separated from the handlebars by at least 10 mm after pressing the handle.

Drum brakes

Brake mechanism is built into the front wheel hub. A braking force is induced by tightening the lever on the handlebar. This force transmitted by cable and lever causes dilation of the brake shoes and

their emphasis on the drum hub. Brake adjustment is made by cable tension.

Checking and adjustment of hydraulic disc brakes

Check the brake lines and their connections for leakages during pressing on the brake lever. If a leakage is found, immediately contact an authorised Kross service station, because a leakage

may result in inoperational brakes. Braking levers may be adjusted to the hand size of the cyclist, ensuring optimum braking efficiency. In most cases, the adjustment is made using a small

Allen screw or a cross-headed screw located in the cover of the brake lever. Hydraulic brakes are equipped with a mechanism which automatically compensates lining wear. In order to perform

brake pressure regulation or replacement of used linings, contact an authorised Kross service station.

Never transport a bicycle with hydraulic brakes with wheels pointing upwards. It may result in inoperational brakes. Clutches of disc brakes must be

protected against sliding out with a special insert, if the bicycle is transported with removed wheels.

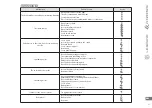

BRAKES

Kross and Le Grand bicycles may use three types of brakes: in the axle (so called torpedo), disc (hydraulic and mechanic), Fig. 23., and rim (v-brake, u-brake).

Fig. 24. In case of bicycles sold for riding in right-sided traffic, the right brake lever operates the rear wheel brake, while the left brake lever operates the front

wheel brake. In case of bicycles sold for riding in the left-sided traffic (e.g. Great Britain), right brake lever operates the front wheel brake, while the left brake

lever operates the rear wheel brake.

Warning: For bikes with hub torpedo (coaster brake), there is only one brake lever and it works on the front brake.

Fig. 23. Disc brake

Fig. 24. V-brake type brake

Fig. 25. Correct setting of brake

pads