15

EN

WHEELS

Wheels should rotate lightly and fluidly, and the tyres should fit well along the entire rim circumference.

Adjustment

Well lubricated and screwed together axles allow traversing thousands of kilometers without the need for bearing replacement in the wheels. Well centered

wheels should also serve well without the need for pulling up the spokes. However, in order to perform these adjustments, one needs experience and

specialist tools.

Transport

In order to remove the wheels for transport, it is enough to unclip the rim brakes (in case of disc brakes, no additional operations are necessary) and loosen the clip

or axle nuts which fix the wheel to the fork or to the frame. Then the wheel is slipped out of the hooks. Once the wheels are removed for the transport, put a special

insert between the pads of disc brakes. After re-installing the wheels, tighten strongly (25-35 Nm) screws at the axle or press the clip. The clip should be difficult to

press so it can be pressed into the hooks of the fork in the locked position.

Air chamber replacement

Air chamber replacement is performed after releasing the air by lifting an edge of the tyre on one side using special, plastic lever. Another lever is used to lift

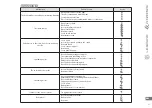

the edge of the tyre a few centimeters away. The third lever allows to lift the edge of the tyre along the entire length. Fig. 50. After air chamber replacement,

pull out the tyre valve as far as possible through an opening in the rim and pump a small amount of air into the air chamber. Slip the tyre back onto the rim

and fill the air chamber to the desired air pressure. If the air chamber valve cartridge needs to be replaced, then in the case of AV type valves a special spanner

is required, Fig. 51. Other valves are replaced by unscrewing the nut, replacing the cartridge and screwing the nut back on. A securing nut is also necessary,

lack of which may result in air losses. Some wheels are constructed on the so called wide axle. Removing them from a shock absorbing fork may require some

experience.

In case of bicycles with rim brakes, keep rims and brake pads in particular cleanliness and control

their wear.

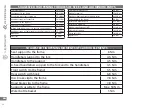

Fast latching mechanism (QR) (wheels, seat bracket)

This system enables fast wheel replacement or seat height adjustment and change. In order for the mechanism to operate correctly and ensure maintaining

appropriate wheel positioning in relation to the frame or the fork as well as prevent the seat from rotating during the ride, the adjustment nut must be adju-

sted properly, to achieve the adequate compression – 20 Nm. In order to increase the compression, twist the adjustment nut clockwise, in order to decrease

it – counterclockwise. After closing the lever, a “CLOSE” mark (closed) is visible, and after opening it – “OPEN” (opened), Fig. 52. When using the fast latching

mechanism for wheel installation, the mechanism should be pressing into the hooks of the fork when it is locked in the locked position. In order to check if

the fast latching mechanism of the wheel is properly set, open the fast latching mechanism, hit the top part of the wheel with your hand, with properly set

mechanism, the wheel should not fall out of the hooks of the front fork.

twist

press

key

AV type valve

open position

force regulation

Fig. 50. Proper use of levers during

tyre removal

Fig. 51. AV type valve

Fig. 52. Fast latching mechanism

Fig. 52.1

»