INSTALLATION

2

13

OPTISONIC 6300

www.krohne.com

06/2019 - 4005857501 - QS OPTISONIC 6300 v2 R01 en

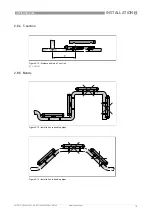

2.8.1 Inlet, outlet and recommended mounting area

To perform an accurate flow measurement preferably mount the sensor rail at least 10 DN

downstream of a flow disturbance like elbow, valve, header or pump. Please follow the

installation recommendations in the next installation position examples.

Note: especially for XT (eXtended Temperature) versions:

Figure 2-9: Inlet, outlet and recommended mounting area

1

t

10 DN

2

t

5 DN

3

OK, 120

°

CAUTION!

•

Always install the sensor at a non-insulated part of the pipe. Remove any insulation if

necessary!

•

After installation, the sensor can be completely insulated. The sensor cable must be kept

away from the hot pipe surface.

•

Always wear protective gloves.