89

INSTRUMENTS AND CONTROLS

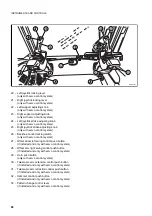

1 - REVERSING GEAR-GEARSHIFT LEVER

DANGER

•

Since no mechanical connection is provided between the gearshift and the engine, if the machine is

parked on a slope it can move freely even with engaged gears; for this reason, always apply the parking

brake, in order to avoid any damage.

•

The machine is equipped with an acoustic alarm that is activated if the operator, with the engine run-

ning, moves the reversing gear lever (1) to position FWD or REV with the seat rotated in any position

different from the correct driving position.

This is a danger signal, since it is absolutely forbidden to carry out any movement with the machine

while working with the backhoe equipment or in any case with the seat rotated by 180° with respect to

the regular driving position. Remember that the operator must carry out any movement of the machine

while seated in the correct driving position, with locked seat and fastened safety belt.

•

Disconnect the connector of the reversing gear-gearshift lever unit before carrying out electric welding

operations on the machine.

Non-compliance with this rule may even result in deadly accidents, since the gear storage, gear selec-

tion and travel direction selection microcircuits may be irreversibly damaged.

IMPORTANT

☞

•

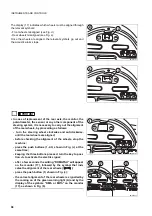

The engine can be started only with the gearshift lever in

neutral position (N).

•

If the operator deems it necessary, the machine may also

be equipped with an acoustic alarm for movements in re-

verse.

This device can be installed on an apposite area on the

rear part of the frame (see 2.4.3 CHECKS FOR TRAVEL-

LING IN REVERSE) and before carrying out any move-

ment in reverse it is recommended to make sure that this

device is functioning perfectly.

To check the functionality of this acoustic alarm, proceed

as follows:

- Start the machine (see “3.6.2 STARTING THE ENGINE”)

- Press the brake pedals.

- Shift the reversing gear lever (1) to the reverse position

R.

If the alarm doesn’t work, have the machine checked by

your Komatsu Utility Dealer.

This is a combined control that serves either to shift gears and to

reverse.

The gears are engaged by means of the push buttons UP (2)

and DOWN (3).

The travelling direction (forward or reverse) is selected by means

of the lever (1).

The normal control of the gearshift is ensured by the semiauto-

matic logic system (SA), with possibility to select the automatic

logic system (AU).

The gearshift control is also provided with a safety code to pre-

vent theft.

+

-

FWD

REV

N

1

2

3

RWA12430

Summary of Contents for 97SF11205

Page 2: ......

Page 12: ...10 THIS PAGE WAS INTENTIONALLY LEFT EMPTY ...

Page 21: ...SAFETY AND ACCIDENT PREVENTION ...

Page 56: ...54 THIS PAGE WAS INTENTIONALLY LEFT EMPTY ...

Page 57: ...THE MACHINE AND ITS OPERATIONS ...

Page 179: ...MAINTENANCE ...

Page 251: ...TECHNICAL SPECIFICATIONS ...

Page 257: ...AUTHORISED OPTIONAL EQUIPMENT ...