PRECAUTIONS TO BE TAKEN DURING MAINTENANCE

44

2.8 PRECAUTIONS TO BE TAKEN DURING MAINTENANCE

2.8.1 WARNING

PLATES

2.8.2 TOOLS

2.8.3 PERSONNEL

DO NOT

START

ENGINE

RWA01210

•

Before starting any maintenance operation, position the ma-

chine on firm and level ground, engage the safety locks either

for the equipment and the controls, stop the engine and apply

the parking brake.

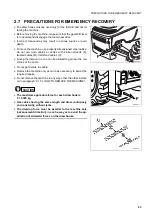

•

If another person starts the engine and operates the controls

while the operator is providing for service, this may result in

serious injuries or even death.

•

To avoid these risks, always attach warning plates to the steer-

ing wheel, to the control levers and to the ignition key before

performing any maintenance operation; if necessary, attach

additional warning tags also around the machine and in partic-

ular on the cab door handles.

RWA01310

RWA02860

•

Use only the tools provided with the machine and high-quality

tools suitable for the tasks to be performed.

•

Do not use worn, damaged, low-quality tools or tools that are

not suitable for the tasks to be performed, in order to avoid any

personal injury.

•

After use, carefully clean the tools and put them in the com-

partment obtained inside the seat support. If the operator

plans to keep on the machine some tools whose dimensions

exceed those of the compartment positioned under the seat,

he can store them in an appropriate tool box positioned on the

rear outer part of the cab. See “3.5.11 ADDITIONAL TOOL

BOX (if provided).”

•

Any maintenance operation must be carried out exclusively by authorized and duly trained personnel; specific

and personal protection measures must be adopted when grinding, welding and when using sledges or heavy

hammers.

•

When assemblying the equipment or cylinder connection pins, use wooden, plastic or in any case not exces-

sively hard tools to check the centering of the holes.

Do not use your fingers, since you run the risk of cutting them.

Summary of Contents for 97SF11205

Page 2: ......

Page 12: ...10 THIS PAGE WAS INTENTIONALLY LEFT EMPTY ...

Page 21: ...SAFETY AND ACCIDENT PREVENTION ...

Page 56: ...54 THIS PAGE WAS INTENTIONALLY LEFT EMPTY ...

Page 57: ...THE MACHINE AND ITS OPERATIONS ...

Page 179: ...MAINTENANCE ...

Page 251: ...TECHNICAL SPECIFICATIONS ...

Page 257: ...AUTHORISED OPTIONAL EQUIPMENT ...