288

ARRANGEMENT FOR THE INSTALLATION OF THE MANUAL HYDRAULIC HAMMER

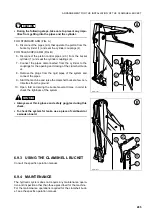

6.10.3 USING THE HAMMER

6.10.4 MAINTENANCE

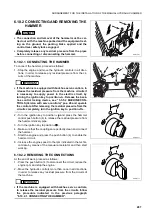

3 - Turn the ignition key to position « » and press the hammer control push button (4) to release the residual pres-

sure from the hammer delivery pipe; after releasing the pressure, press the push button (4) again to discon-

nect the circuit.

4 - Turn the ignition key to position « ».

5 - Disconnect the hammer.

CAUTION

•

If quick attachments are not provided, place sealing plugs with the relevant gaskets on the couplings of

the machine and of the hammer.

DANGER

•

Make sure that the plugs are properly tightened and that there are no leakages; if the circuit is inadvert-

ently pressurized, small leakages can be turned into thin jets that may perforate the skin or injure the

eyes.

•

Always wear thick gloves and safety goggles to carry out this check.

•

To check the system for leaks, use a piece of cardboard or a wooden board.

Consult the specific operation manual.

The hydraulic system does not require any maintenance operation and inspection other than those prescribed for

the machine.

For the maintenance operations required for the hammer, see the specific operation manual.

Summary of Contents for 97SF11205

Page 2: ......

Page 12: ...10 THIS PAGE WAS INTENTIONALLY LEFT EMPTY ...

Page 21: ...SAFETY AND ACCIDENT PREVENTION ...

Page 56: ...54 THIS PAGE WAS INTENTIONALLY LEFT EMPTY ...

Page 57: ...THE MACHINE AND ITS OPERATIONS ...

Page 179: ...MAINTENANCE ...

Page 251: ...TECHNICAL SPECIFICATIONS ...

Page 257: ...AUTHORISED OPTIONAL EQUIPMENT ...