MAINTENANCE PLAN

227

4.7.8.f

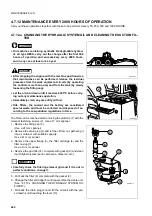

CHECKING THE HYDRAULIC TRANSMIS-

SION OIL LEVEL

4.7.8.g

CHECKING THE WHEEL NUT DRIVING

TORQUE

DANGER

•

The level must be checked with running engine and trans-

mission oil at operating temperature; be very careful, in

order to avoid burns.

•

Let all the work equipment safety locks engaged, apply

the parking brake and do not move the gearshift lever.

•

If it is necessary to add oil, stop the engine before open-

ing the engine hood.

The dipstick (1) can be reached after opening the engine hood.

See “3.5.1 ENGINE HOOD”.

The oil level must be checked with the engine idling and the oil at

running temperature.

The oil must always reach the maximum level or be very near it.

To top up, use the dipstick opening (1) and the prescribed oil.

(See “4.3 FUEL, COOLANT AND LUBRICANTS”).

RWAB0310

MAX.

MIN.

1

This check serves to restore the correct driving torque of the

wheels on the hubs.

The driving torque must be checked by means of a dynamomet-

ric spanner (1) set according to the values indicated in para-

graph “4.4.2 SPECIFIC DRIVING TORQUES”. (Use a 32 mm

spanner).

IMPORTANT

☞

•

Do not increase the specified driving torque and keep it

within the prescribed ranges.

•

When the driving torque must be checked, do not lubri-

cate the thread.

RWA28390

1

Summary of Contents for 97SF11205

Page 2: ......

Page 12: ...10 THIS PAGE WAS INTENTIONALLY LEFT EMPTY ...

Page 21: ...SAFETY AND ACCIDENT PREVENTION ...

Page 56: ...54 THIS PAGE WAS INTENTIONALLY LEFT EMPTY ...

Page 57: ...THE MACHINE AND ITS OPERATIONS ...

Page 179: ...MAINTENANCE ...

Page 251: ...TECHNICAL SPECIFICATIONS ...

Page 257: ...AUTHORISED OPTIONAL EQUIPMENT ...