MAINTENANCE PLAN

235

4.7.10.f DRAINING THE HYDRAULIC OIL TANK

(Only for machines in which the synthet-

ic biodegradable oil type HEES is used)

DANGER

•

After stopping the engine, with the machine in the correct

position for the performance of maintenance operations,

eliminate the residual pressures from the equipment (by

moving the controls more than once) and from the tank

(by slowly loosening the filling cap).

•

Let the oil cool down until it reaches 40÷45°C before car-

rying out any maintenance operation.

•

Immediately clean any area dirty with oil.

This operation serves to let the condensate accumulated on the

tank bottom flow out of the tank itself; for this purpose, carry out

the following operations in the given sequence:

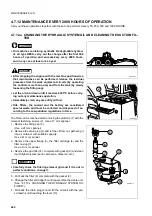

1 - Remove the screws (1) and the platform (2).

Use a 17 mm spanner.

2 - Loosen the filling cap (3) to release the residual pressure

from the tank.

use a 24 mm spanner.

3 - Remove the drain plug (4) until the condensate has flown out

of the tank completely.

Use a 41 mm spanner.

4 - Put back the filling cap (3) and the platform (2).

IMPORTANT

☞

•

The draining of the tank must be carried out at tempera-

tures exceeding 0°C, before starting the engine; when the

temperature is below 0°C, the hydraulic oil tank must be

drained at the end of work, or in any case when the tem-

perature of the machine is sufficiently high to prevent the

condensate from freezing and allow it to flow out of the

tank without problems.

RWA34460

2

1

RWA34470

4

3

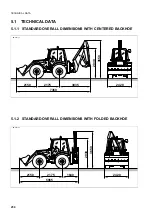

Summary of Contents for 97SF11205

Page 2: ......

Page 12: ...10 THIS PAGE WAS INTENTIONALLY LEFT EMPTY ...

Page 21: ...SAFETY AND ACCIDENT PREVENTION ...

Page 56: ...54 THIS PAGE WAS INTENTIONALLY LEFT EMPTY ...

Page 57: ...THE MACHINE AND ITS OPERATIONS ...

Page 179: ...MAINTENANCE ...

Page 251: ...TECHNICAL SPECIFICATIONS ...

Page 257: ...AUTHORISED OPTIONAL EQUIPMENT ...