285

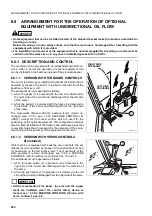

ARRANGEMENT FOR THE INSTALLATION OF THE CLAMSHELL BUCKET

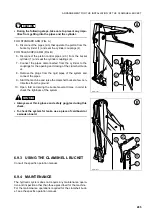

6.9.3 USING THE CLAMSHELL BUCKET

6.9.4 MAINTENANCE

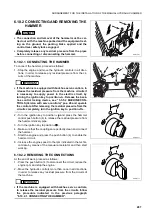

CAUTION

•

During the following steps, take care to prevent any impu-

rities from getting into the pipes and the cylinder.

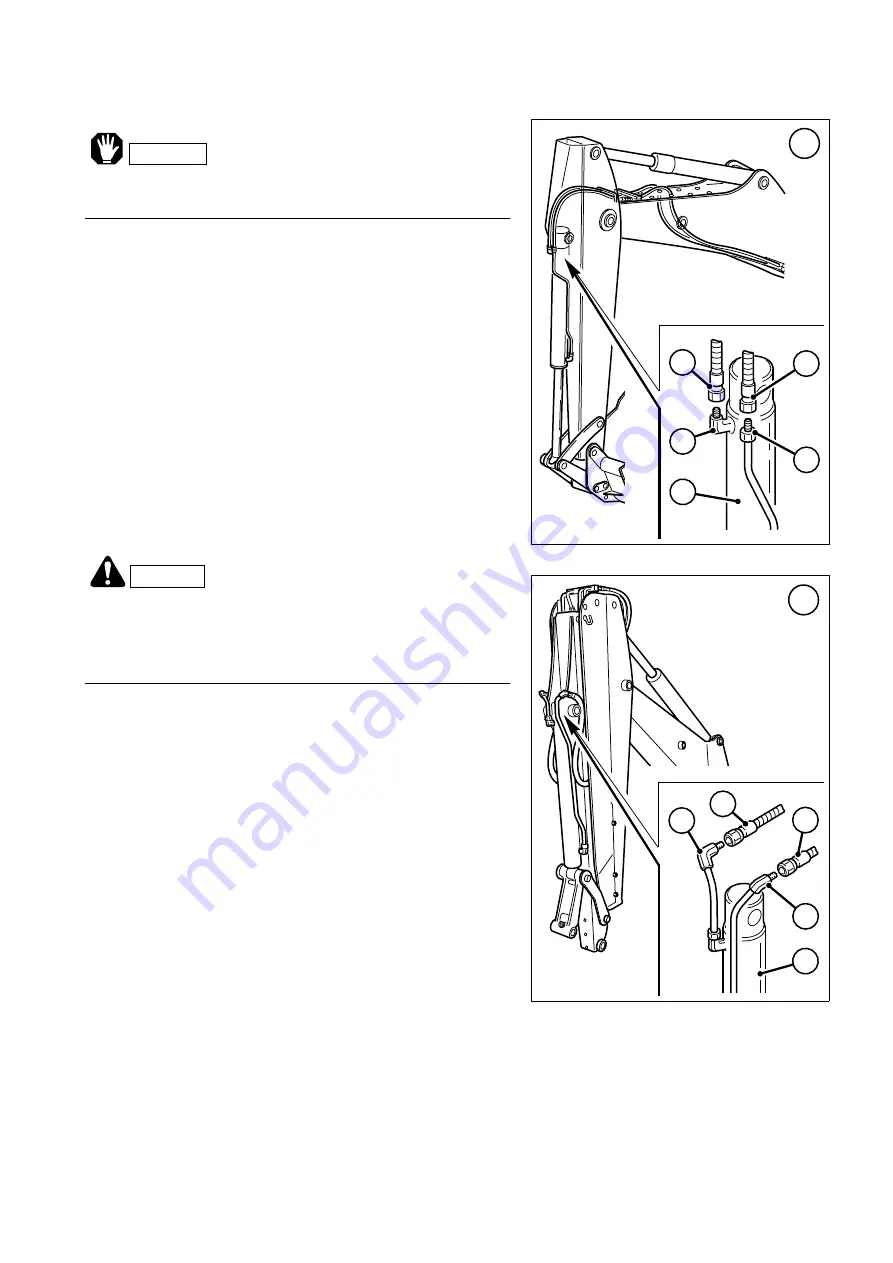

FOR STANDARD ARM (FIG. A)

6 - Disconnect the pipes (2-3) that operate the piston from the

bucket cylinder (1) and seal the cylinder couplings (4).

FOR TELESCOPIC ARM (FIG. B)

6 - Disconnect the piston control pipes (2-3) from the bucket

cylinder (1) and seal the cylinder couplings (4).

7 - Connect the pipes disconnected from the cylinder to the

couplings for the opening and closing of the clamshell buck-

et.

8 - Remove the plugs from the rigid pipes of the system and

connect the pipes.

9 - Start the machine and raise the clamshell bucket a few cen-

trimetres from the ground.

10 - Open, fold and swing the bucket several times, in order to

check the tightness of the system.

DANGER

•

Always wear thick gloves and safety goggles during this

check.

•

To check the system for leaks, use a piece of cardboard or

a wooden board.

RWA17400

A

1

4

2

3

4

1

2

3

4

4

RWA17390

B

Consult the specific operation manual.

The hydraulic system does not require any maintenance opera-

tion and inspection other than those prescribed for the machine.

For the maintenance operations required for the clamshell buck-

et, see the specific operation manual.

Summary of Contents for 97SF11205

Page 2: ......

Page 12: ...10 THIS PAGE WAS INTENTIONALLY LEFT EMPTY ...

Page 21: ...SAFETY AND ACCIDENT PREVENTION ...

Page 56: ...54 THIS PAGE WAS INTENTIONALLY LEFT EMPTY ...

Page 57: ...THE MACHINE AND ITS OPERATIONS ...

Page 179: ...MAINTENANCE ...

Page 251: ...TECHNICAL SPECIFICATIONS ...

Page 257: ...AUTHORISED OPTIONAL EQUIPMENT ...