268

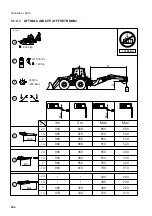

BACKHOE TELESCOPIC ARM

6.5.4 MAINTENANCE

6.5.4.1

ADJUSTING THE GUIDE SLACK

The telescopic arm requires two maintenance operations:

1 - Lubrication of the joints (see “4.5.4 LUBRICATION DIAGRAM”).

2 - Adjustment of the slide guide (8) slack, which must be carried out occasionally, when impacts or vibrations are

noticed during work.

IMPORTANT

☞

•

Lubricate the telescopic arm guides only if the sliding shoes are made of brass. Plastic shoes do not

require lubrication.

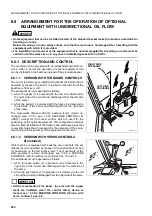

DANGER

•

When leaving the operator’s seat for the adjustment of the

guides, remove the ignition key.

•

Adjust the screws and guides one by one.

•

Do not place tools in the space between the safety locks

and the arm.

1 - Position the machine on flat ground and lower the stabilizers.

2 - Raise the boom, fold the bucket completely and extend the

telescopic part (7) completely.

3 - Fold the arm until the slide guides (8) are perpendicular to

the ground and in any case positioned so that the extendable

part is completely free and does not strain the guides.

4 - Stop the engine.

5 - Check the side on which the adjusting dowels (9) of the

guides protrude more. Adjust by working on this side only.

RWA03590

7

8

9

Summary of Contents for 97SF11205

Page 2: ......

Page 12: ...10 THIS PAGE WAS INTENTIONALLY LEFT EMPTY ...

Page 21: ...SAFETY AND ACCIDENT PREVENTION ...

Page 56: ...54 THIS PAGE WAS INTENTIONALLY LEFT EMPTY ...

Page 57: ...THE MACHINE AND ITS OPERATIONS ...

Page 179: ...MAINTENANCE ...

Page 251: ...TECHNICAL SPECIFICATIONS ...

Page 257: ...AUTHORISED OPTIONAL EQUIPMENT ...