44

UNDERSTANDING SWASHPLATE CONTROL SYSTEMS

Currently, there are several different types of control systems

available on the market. Although the mechanical methods for

transferring control to the swashplate vary, the different control

systems can be broken down into two categories: 1 Servo

(conventional) and CCPM (Cyclic/ Collective Pitch Mixing).

The following is an explanation of the two most popular types of

swashplate control.

1. 1 Servo Standard Swashplate Control

The 1 Servo Standard System is found in a wide variety of radio

controlled helicopters. The term “1 Servo” means that the control

system requires one servo to operate each separate swashplate

function. With this system, a total of three servos is required to

operate the three main swashplate functions, which are aileron

(roll), elevator (pitch), and collective functions. With this type of

control system, each servo works independently and is assigned

to a specific function. In other words, the aileron (roll) servo is

assigned to move only the aileron (roll) function, as is the

elevator (pitch) servo, etc. Since these servos operate completely

independently of each other, the servo torque to each control

surface is limited to the maximum torque rating of the

servos used.

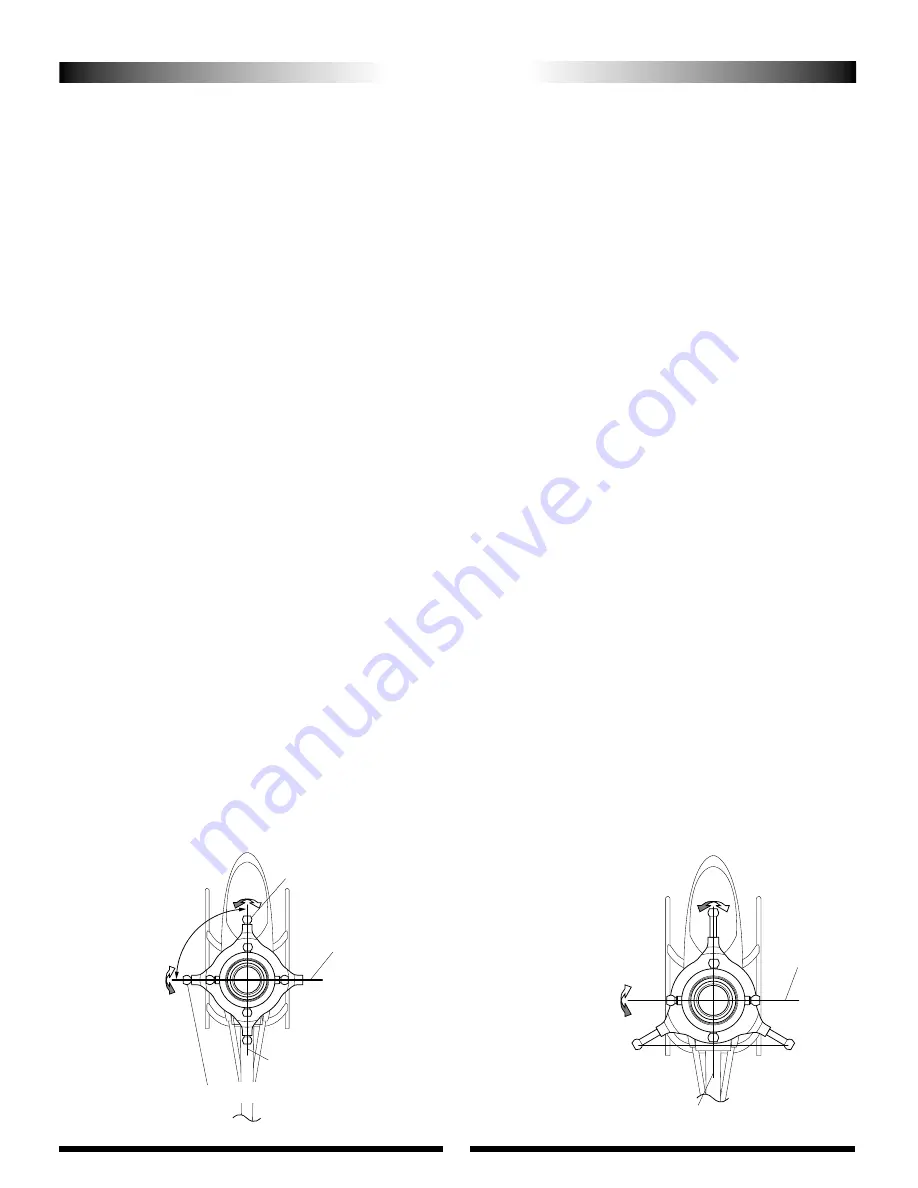

The 1 Servo Standard System swashplate is designed so that the

lower swashplate ring control balls are spaced at 90° to each

other. This system is also most commonly arranged so that the

aileron (roll) axis of the swashplate is positioned at 90° to the

main mechanics of the helicopter, and the elevator (pitch) axis is

parallel to the mechanics. Please refer to the diagram at right

for clarification.

With this type of system, it is necessary for the helicopter to be

designed using an intermediate mechanical mixing system so that

the control inputs can be transferred from the three independent

servos to the swashplate in such a manner that the three controls

can be achieved. This mechanical mixing system allows the

swashplate to both roll (aileron) and pitch (elevator), as well as

slide up and down the main rotor shaft for collective pitch inputs.

These mechanical mixing systems generally require the use of

many ball bearings and control rods to achieve this result.

2. 120 3-Servo CCPM Swashplate Mixing

The JR 120° CCPM or Cyclic/Collective Pitch Mixing System offers

the user a control system that can accomplish the same control

inputs as the 1 Servo Standard System mentioned above, but with

increased precision and reduced complexity.

The JR CCPM System utilizes three servos for the three main

controls: aileron (roll), elevator(pitch) and collective. The CCPM

lower swashplate ring is designed with only three control balls,

spaced at 120° from each other, hence the 120° CCPM

designation. Although the control balls are not at 90° as in the

Standard System, the aileron (roll) axis is still parallel to the main

mechanics of the helicopter, and the elevator (pitch) axis still

functions at 90° to the mechanics as does the 1 Servo System.

Please refer to the diagram below for clarification.

The main difference in the way that these two systems operate is

that unlike the 1 Servo System where the three servos work

completely independent from each other, the CCPM Systems work

as a team to achieve the same control inputs. For example, if an

aileron (roll) input is given, two servos work together to move the

swashplate left and right. If an elevator (pitch) input is given, all

three servos work together to move the swashplate fore and aft.

For collective, it’s also the strength of three servos that will move

the swashplate up and down the main rotor shaft. With two to

three servos working at the same time during any given control

input, servo torque is maximized and servo centering is also

increased. In addition to these benefits, CCPM achieves these

control responses without the need for complex mechanical

mixing systems that require many more control rods and parts

to set up.

This amazing CCPM control is achieved through special CCPM

swashplate mixing that is preprogrammed into many of today’s

popular radio systems. Since the 120° CCPM function is

preprogrammed, CCPM is no more complicated to set up than a

conventional 1 Servo Standard System. When you factor in the

reduced parts count and easy programming, CCPM is actually

easier to set up and operate than many conventional systems.

For JR radio owners, please refer to the radio information

contained at the front of this manual or on the following page to

determine if your radio

system has the

CCPM function.

For other brands

of radio systems,

please contact the

radio manufacturer

for CCPM

information.

Please note that it

is not possible to

program a non-

CCPM radio

system for

CCPM operation.

Elevator control ball is in

line with helicopter frame

Aileron Axis

Elevator Axis

Aileron control ball

is 90° to elevator

control ball and

helicopter frame

Standard “1 Servo” Swashplate System

Elevator Axis

Aileron Axis

JR 120° 3 Servo CCPM Control System

120°

JRP9012.46 Robinson R22 Manual 10/6/00 5:06 PM Page 44