Intel® Server System S9200WK Product Family Setup and Service Guide

86

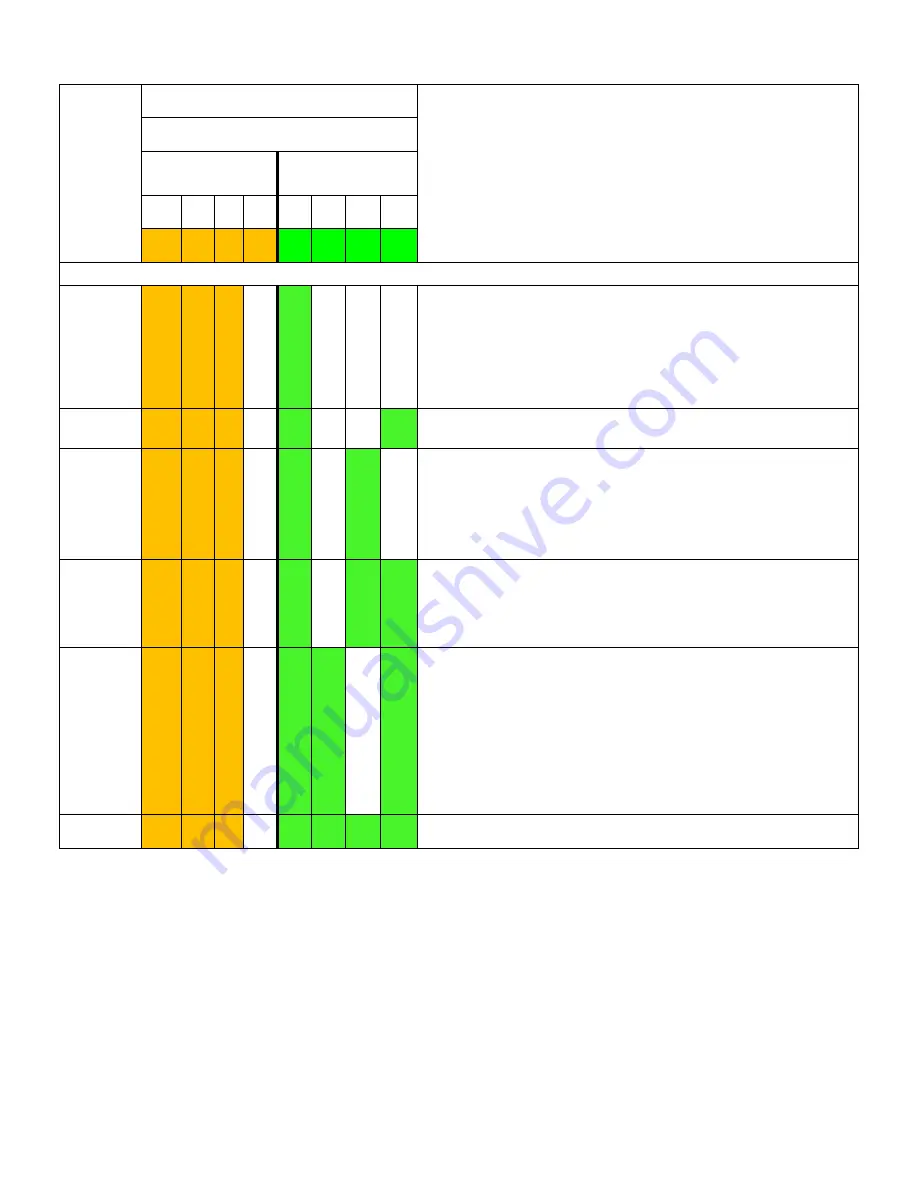

Table 4. MRC fatal error codes

Checkpoint

Diagnostic LED Decoder

Description

1

= LED On,

0

= LED Off

Upper Nibble

(Amber - Read 1st)

Lower Nibble

(Green - Read 2nd)

MSB

LSB

8h

4h 2h 1h 8h 4h 2h 1h

MRC Fatal Error Codes

E8h

1

1

1

0

1

0

0

0

No usable memory error

01h = No memory was detected from SPD read, or invalid config that

causes no operable memory.

02h = Memory DIMMs on all channels of all sockets are disabled due to

hardware memtest error.

03h = No memory installed. All channels are disabled.

E9h

1

1

1

0

1

0

0

1

Memory is locked by Intel Trusted Execution Technology and is

inaccessible

EAh

1

1

1

0

1

0

1

0

DDR4 channel training error

01h = Error on read DQ/DQS (Data/Data Strobe) init

02h = Error on Receive Enable

03h = Error on Write Leveling

04h = Error on write DQ/DQS (Data/Data Strobe

EBh

1

1

1

0

1

0

1

1

Memory test failure

01h = Software memtest failure.

02h = Hardware memtest failed.

EDh

1

1

1

0

1

1

0

1

DIMM configuration population error

01h = Different DIMM types (RDIMM, LRDIMM) are detected installed in

the system.

02h = Violation of DIMM population rules.

03h = The 3rd DIMM slot cannot be populated when QR DIMMs are

installed.

04h = UDIMMs are not supported.

05h = Unsupported DIMM Voltage.

EFh

1

1

1

0

1

1

1

1 Indicates a CLTT table structure error