7.0

INSTALLATION

TS1A–13A

http://air.irco.com

12

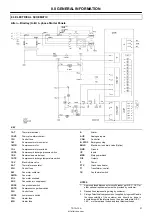

7.2 DISCHARGE AND CONDENSATE PIPING

KEY

1. Compressor

2. Air Receiver

3. Air Dryer

4. Compressed air filters

5. System demand points

6. Valve, vent

7. Valve, isolation

8. Valve, condensate

9. Valve, bypass

It is essential when installing a new dryer [3], to review the total air

system. This is to ensure a safe and effective total system. One item

which should be considered is liquid carryover. Installation of air dryers

[3] is always good practice since properly selected and installed they

can reduce any liquid carryover to zero.

Piping should be at least as large as the discharge connection of the

equipment. All piping and fittings should be suitably rated for the

operating pressure.

It is good practice to locate by–pass piping close to the dryer and to

install line filters [4].

IMPORTANT: The drain line must slope downward from the base to

work properly. For ease of inspection of the automatic drain trap

operation, the drain piping should include an open funnel.

CAUTION

The use of plastic bowls on line filters and other plastic air line

components without metal guards can be hazardous. Their safety

can be affected by either synthetic coolants or the additives used

in mineral oils. From a safety standpoint, metal bowls should be

used on any pressurized system.

NOTICE

Do not use the dryer to support the piping.

7.3

ELECTRICAL

CAUTION

This procedure should only be carried out by a qualified

electrician, electrical contractor or your local Ingersoll Rand

Distributor or Air Center.

The dryer should be properly grounded / earthed in accordance with

Local and National Code requirements..

Installation of this dryer must be in accordance with recognized

electrical codes and any local Health and Safety Codes.

The dryer must have its own isolator situated adjacent to it. The fuse

protecting the circuit and the dryer must be selected in accordance with

local and national code requirements on the basis of the data provided

in the general information section

Feeder cables should be sized by the customer/electrical contractor to

ensure that the circuit is balanced and not overloaded by other

electrical equipment. The length of wiring from a suitable electrical feed

point is critical as voltage drops may impair the performance of the

dryer.

Feeder cable connections to incoming terminals L1–L2–L3 should be

tight and clean.

The applied voltage must be compatible with the data plate ratings.

NOTICE

The control circuit transformer has different voltage tappings.

Ensure that these are set for the specific applied voltage prior to

starting.

A hole is provided for incoming power connection. If it is necessary to

make a hole in the control box in a different location, care should be

taken to not allow metal shavings to enter the starter and other electrical

components within the box. If another hole is used, the original hole

must be blocked off.

The feeder cable must be suitably glanded into the electrical box to

ensure that dirty air does not by–pass.

On completion of electrical installation, check that fan motor rotation is

correct. Cooling air must discharge upwards.

Summary of Contents for TS10A

Page 2: ......

Page 10: ...5 0 SAFETY TS1A 13A http air irco com 8 5 3 TEXT DECALS NORTH AMERICA ...

Page 50: ......

Page 52: ......

Page 60: ...5 0 SECURITE TS1A 13A http air irco com 8 5 3 DÉCALCOMANIES DES TEXTES AMÉRIQUE DU NORD ...

Page 101: ......

Page 102: ......

Page 104: ......

Page 112: ...5 0 SEGURANÇA TS1A 13A http air irco com 8 5 3 AUTOCOLANTES DE TEXTO AMÉRICA DO NORTE ...

Page 152: ......

Page 161: ...5 0 SEGURIDAD TS1A 13A http air irco com 8 5 3 CALCOMANÍAS DE TEXTO AMÉRICA DEL NORTE ...

Page 203: ......

Page 204: ......