49

sERVICINg

Ideal Logic Code Combi -

Installation and Servicing

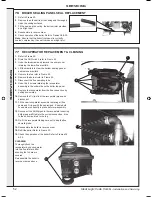

68 DIVERTER VaLVE INTERNaL CaRTRIDgE REpLaCEMENT

FRONT CaRTRIDgE REpLaCEMENT

1.

Refer to Frame 49.

2.

Drain the boiler. Refer to Frame 63.

3.

Remove the diverter valve head. Refer

to Frame 58.

4.

Unscrew the top connection to access

the internal cartridge.

5.

Fit the new valve mechanism ensuring

the correct fit of the pin.

6.

Reassemble in reverse order.

7.

Refill the boiler. Refer to Frame 30.

8.

Check operation of the boiler. Refer to

Frames 38 & 39.

REaR CaRTRIDgE REpLaCEMENT

1.

Refer to Frame 49.

2.

Drain the boiler. Refer to Frame 63.

3.

Remove the diverter valve head. Refer to Frame 58.

4.

Remove the flow pipe. Refer to Frame 74 no. 13.

5.

Disconnect the CH flow pipe and DHW outlet pipe union connections underneath

the boiler. Refer to Frame 63.

6.

Remove the plate heat exchanger LH fixing screw. Refer to Frame 69.

7.

Remove the screw retaining the brass block to the bottom of the boiler casing

and lift the brass block clear of the boiler.

8.

Unscrew the rear cartridge connection.

9.

Fit the new valve mechanism ensuring the correct fit of the pin.

10.

Reassemble in reverse order.

11.

Refill the boiler. Refer to Frame 30.

12.

Check operation of the boiler. Refer to Frames 38 & 39.

FRONT CaRTRIDgE

REaR CaRTRIDgE

3

4

9

8

1.

Refer to Frame 49.

2.

Drain the boiler. Refer to Frame 63.

3.

Remove condensate trap/siphon. Refer to Frame 59.

4.

Remove the diverter valve actuator. Refer to Frame 58.

5.

Remove the 2 allen screws securing the plate heat exchanger to

the brass housings.

6.

Manoeuvre the plate heat exchanger out of the top LH or centre

of the controls area.

7.

Fit the new plate heat exchanger, using the new o-rings supplied.

Note.

The mounting pins are offset so the correct position can be

defined from the location of the holes on the brass mounting.

8.

Reassemble in reverse order.

9.

Refill the boiler. Refer to Frame 30.

10.

Check operation of the boiler. Refer to Frames 38 & 39.

69 DhW pLaTE hEaT ExCh. REpLaCEMENT

5

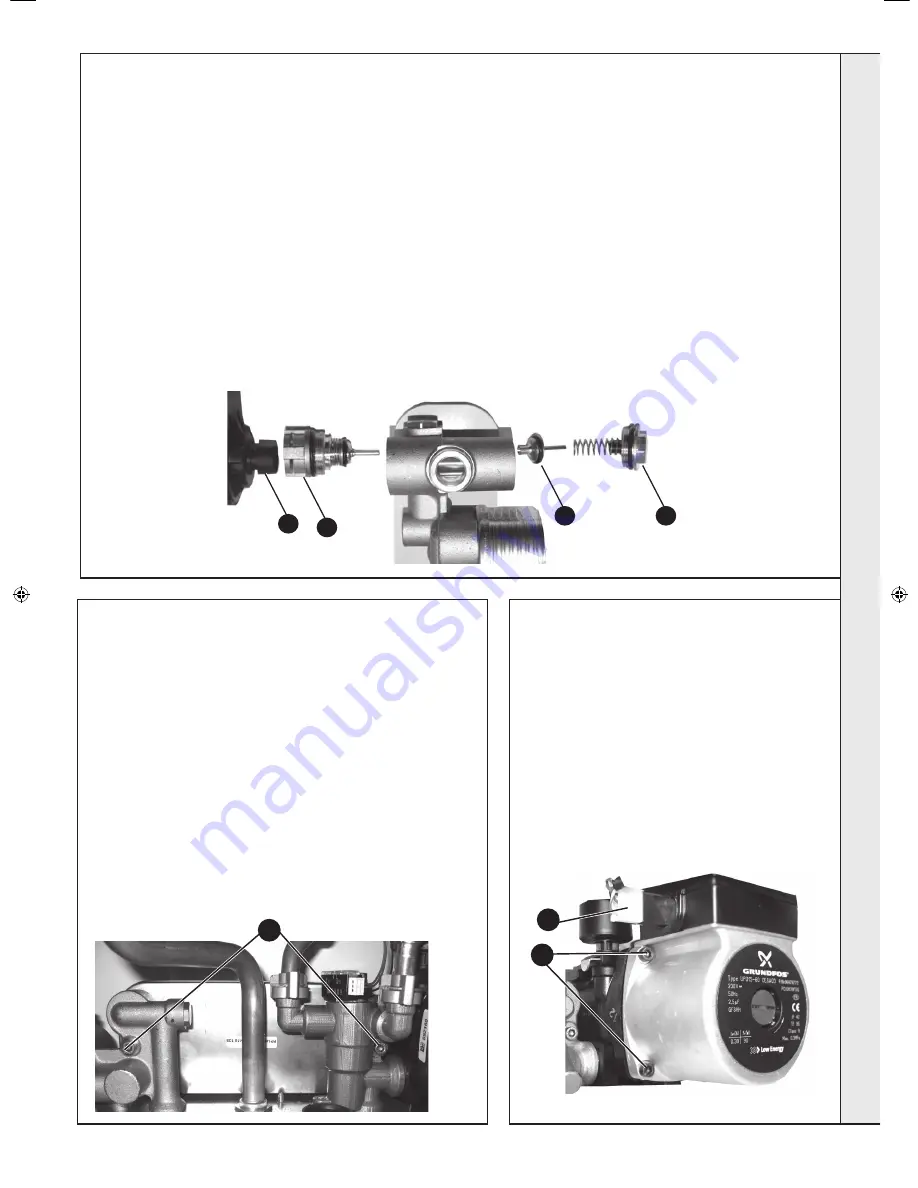

70 pUMp hEaD REpLaCEMENT

3

4

1.

Refer to Frame 49.

2.

Drain the boiler. Refer to Frame 63.

3.

Disconnect the electrical lead from the pump.

4.

Remove the 4 Allen screws retaining the pump

head.

5.

Remove the pump head.

6.

Fit the new pump head.

7.

Reassemble in reverse order.

8.

Refill the boiler. Refer to Frame 38.

9.

Check operation of the boiler. Refer to Frames 38

& 39.

s

ER

VICIN

g

206279-1.indd 49

06/01/2011 09:10:43

Summary of Contents for LOGIC Code Combi 26

Page 2: ...2 Ideal Logic Code Combi Installation and Servicing ...

Page 61: ......