48

sERVICINg

Ideal Logic Code Combi -

Installation and Servicing

66 pUMp aUTOMaTIC aIR VENT REpLaCEMENT

1.

Refer to Frame 49.

2.

Drain the boiler. Refer to Frame 63.

3.

Remove the expansion vessel. Refer to

Frame 75.

4.

Firstly, increase access area by

disconnecting the 22mm pipe connection

at top of pump chamber and bottom of heat

exchanger and remove pipe Refer to Frame

65 (no’s 5,6 & 7).

5.

The automatic air vent head is retained in

the pump body with a bayonet connection.

The air vent head and float assembly is

removed by turning the head anti-clockwise

(viewed from above) and pulling upwards.

6.

Reassembly is the reverse of the above.

Ensure the air vent head ‘o’ ring seal is in

place when refitting and the new ‘o’ ring is

fitted to the return pipe top connection.

7.

Ensure the air vent cap is loose.

8.

Refill the boiler. Refer to Frame 30. Check

for leaks around the new air vent joint.

9.

Check the operation of the boiler. Refer to

Frames 38 & 39.

5

Dust Cap

4

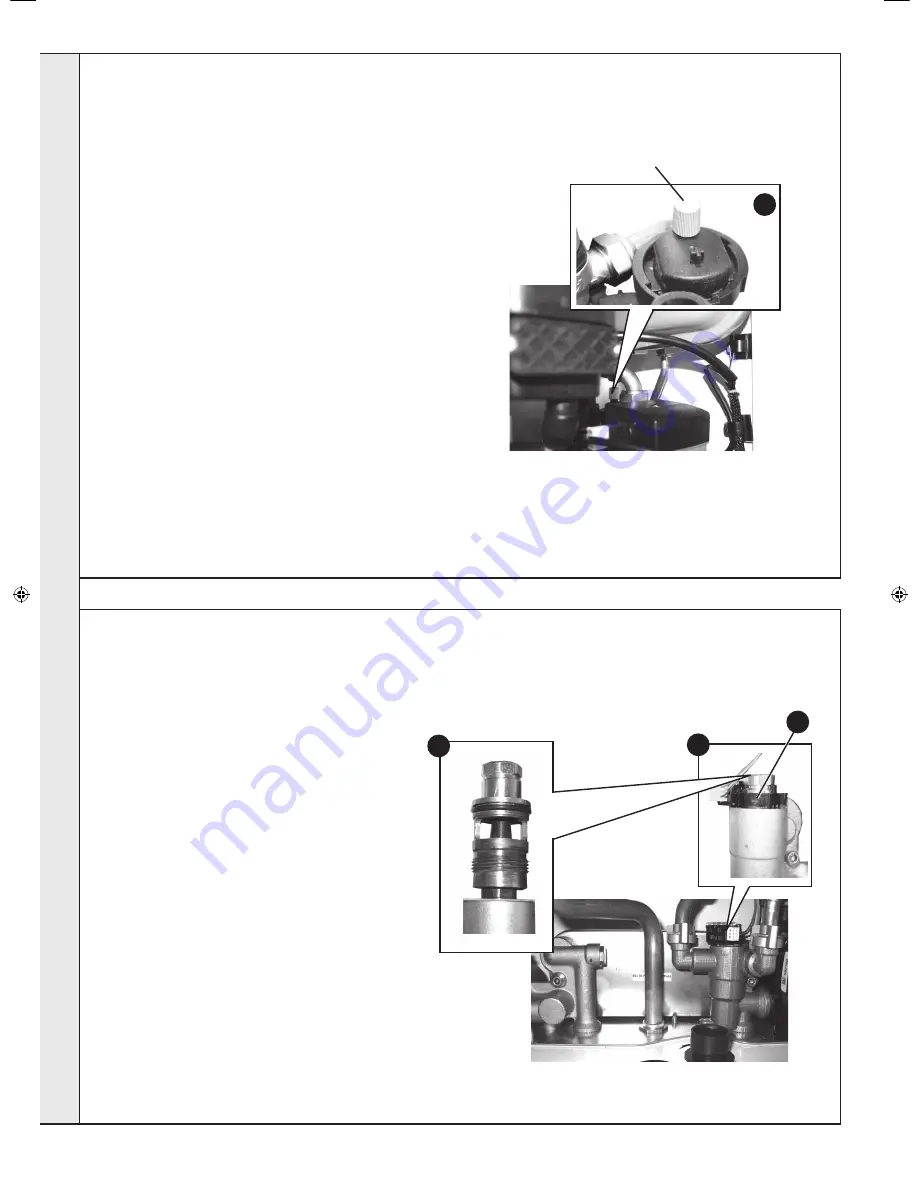

67 DhW FLOW TURBINE CaRTRIDgE REpLaCEMENT

1.

Refer to Frame 49.

2.

Drain the DHW circuit. Refer to Frame 63.

3.

Remove condensate trap/siphon. Refer to

Frame 59.

4.

Remove the DHW flow turbine sensor. Refer

to Frame 62.

5.

Unclip and disconnect the DHW pipes from

the inlet manifold

6.

Unscrew the top connection to access the

internal part.

7.

Fit the new turbine cartridge.

8.

Refit the turbine flow sensor

9.

Reassemble in reverse order.

10.

Refill the boiler. Refer to Frame 30.

11.

Check operation of the boiler. Refer to

Frames 38 & 39.

6

8

sER

VICIN

g

206279-1.indd 48

06/01/2011 09:10:42

Summary of Contents for LOGIC Code Combi 26

Page 2: ...2 Ideal Logic Code Combi Installation and Servicing ...

Page 61: ......