51

sERVICINg

Ideal Logic Code Combi -

Installation and Servicing

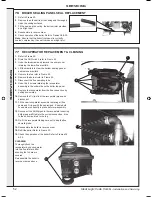

74 hEaT ENgINE RENEWaL

Refer also to Frame 6 - ‘Boiler Exploded View’

IMpORTaNT

Before starting the removal procedure, protect the gas and

electrical controls with a waterproof sheet or plastic bag.

1.

Refer to Frame 49.

2.

Drain the boiler. Refer to Frame 63.

3.

Remove the sump cover, lift the flue manifold upward and pull

the lower end forward to disengage.

4.

Remove the fan / venturi assembly and place on one side.

Refer to Frame 50.

5.

Remove the burner and place on one side. Refer to Frame 52.

6.

Remove the ignition and detection electrodes and divertor

actuator head. Refer to Frames 54, 55 and 58.

7.

Remove the spark generator. Refer to Frame 56.

8.

Remove the gas valve. Refer to Frame 57.

9.

For improved access remove the expansion vessel. Refer to

Frame 75.

10.

Remove the no flow thermistor. Refer to Frame 73.

11.

Remove the 2 M5 screws retaining the gas valve mounting

bracket and transfer bracket to the new heat exchanger.

12.

Disconnect leads from flow and return thermistors.

13.

Undo the return pipe union nut and remove the retaining

spring clip and remove pipe.

14.

Unclip and disconnect the DHW pipe off the brass inlet

manifold and swing to one side.

15.

Undo the flow pipe union nut and remove pipe.

16.

Remove the condensate rubber pipe. Refer to Frame 59, no. 2.

17.

Remove the two heat exchanger fixing screws.

18.

Remove the Heat exchanger, slide to the right out of location

bracket.

19.

Reassemble in reverse order, ensuring the heat exchanger

LH retaining bracket is correctly positioned. Replace

any new ‘o’ rings supplied with new heat exchanger and

replacing gaskets or seals if any sign of damage is evident.

17

13

15

11

When replacing the spring clips located on the return

pipe connection, ensure clip is oriented to correctly match

connecting pipe diameters.

20.

Ensure the trap/siphon is filled with water. Refer to Frame 59.

21.

Refill the boiler. Refer to Frame 30.

22.

Check operation of the boiler. Refer to Frames 38 & 39.

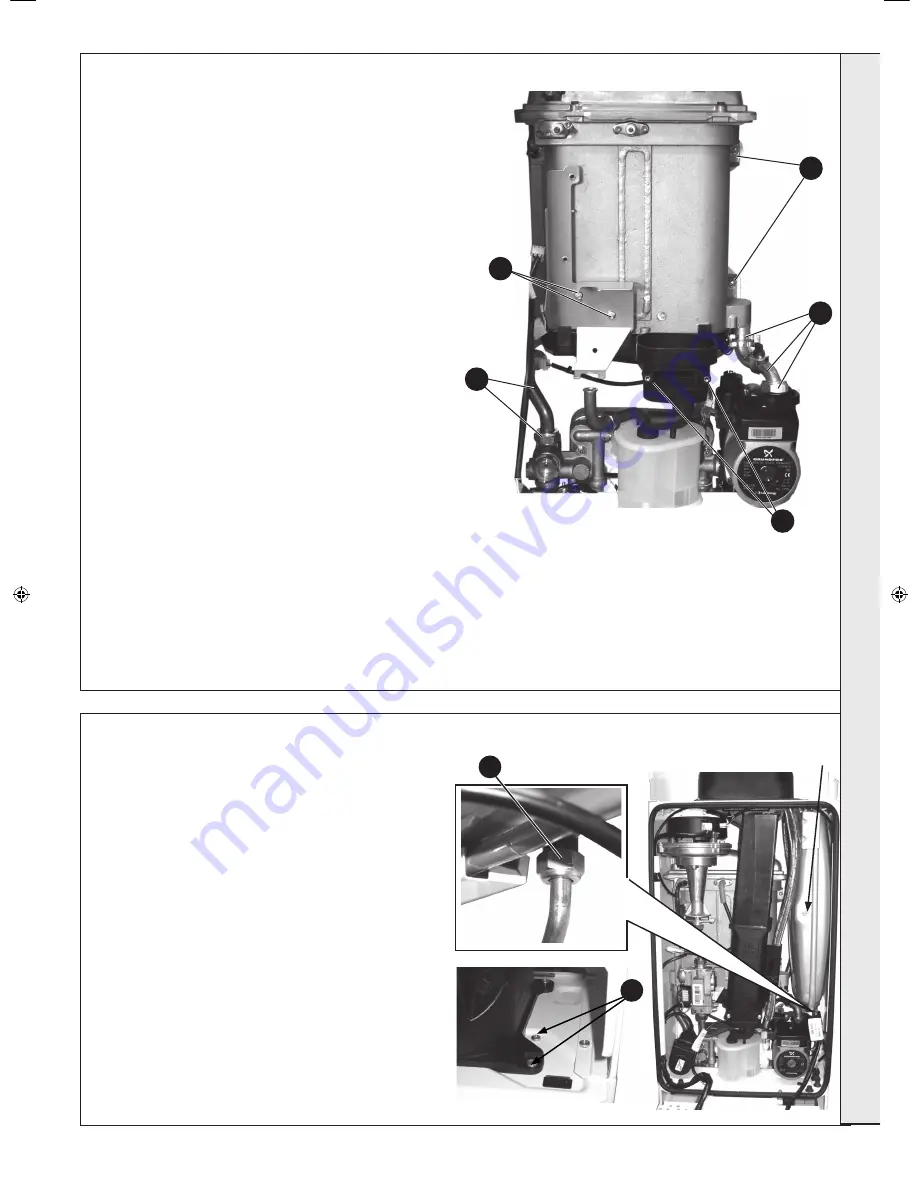

75 ExpaNsION VEssEL REChaRgINg & REpLaCEMENT

9

10

REChaRgINg

1.

Refer to Frame 49.

2.

Relieve system pressure through CH drain point (Refer to

Frame 63).

3.

Remove the charge point cover.

4.

Recharge the tank pressure to 0.75 bar.

5.

Re-assemble in reverse order

6.

Check operation of the boiler. Refer to Frames 38 & 39.

REpLaCEMENT

7.

Refer to Frame 49.

8.

Drain the boiler CH circuit. Refer to Frame 63.

9.

Unscrew the union nut on the vessel water connection pipe.

10.

Support the expansion vessel and unscrew the 2 screws

from the securing clamp, located on the top of the boiler, and

remove. (Note the position of the bracket on the vessel)

11.

Remove the expansion vessel.

12.

Fit the new expansion vessel.

13.

Reassemble in reverse order.

14.

Refill the boiler. Refer to Frame 30.

15.

Check operation of the boiler. Refer to Frames 38 & 39.

Recharge Point

3

s

ER

VICIN

g

206279-1.indd 51

06/01/2011 09:10:46

Summary of Contents for LOGIC Code Combi 26

Page 2: ...2 Ideal Logic Code Combi Installation and Servicing ...

Page 61: ......