9

isar -

Installation and Servicing

GENERAL

4

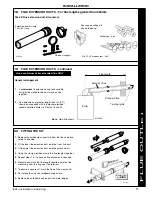

SYSTEM REQUIREMENTS - CH (continued) and Hot Water

General

1. The installation must comply with all relevant national and

local regulations.

2. The installation should be designed to work with flow

temperatures of up to 82

o

C.

3. All components of the system must be suitable for a working

pressure of 3 bar and temperature of 110

o

C. Extra care should

be taken in making all connections so that the risk of leakage

is minimised.

The following components are incorporated within the

appliance:

a.

Circulating pump.

b.

Safety valve, with a non-adjustable preset lift pressure of

3 bar.

c.

Pressure gauge, covering a range of 0 to 6 bar.

d.

An 8-litre expansion vessel, with an initial charge pressure

of 0.75 bar.

4. 'Make-up' Water. Provision must be made for replacing water

loss from the system, either :

a.

From a manually filled 'make-up' vessel with a readily

visible water level. The vessel should be mounted at

least 150mm above the highest point of the system and

be connected through a non-return valve to the system,

fitted at least 150mm below the 'make-up' vessel on the

return side of the radiators.

or

b.

Where access to a 'make-up' vessel would be difficult,

by pre-pressurisation of the system.

The maximum cold water capacity of the system should

not exceed 143 litres, if not pressurized. However, if

the system is to be pressurized, the efficiency of the

expansion vessel will be reduced and a larger vessel

(or smaller system volume) may be necessary. If the

capacity of the vessel is not considered sufficient for

this, or for any other reason, an additional vessel

MUST be installed on the return to the boiler.

Guidance on vessel sizing is given in Frame 3.

5. Filling. The system may be filled by the following method:

a.

Through a temporary hose connection from a 'draw-off'

tap, supplied from a service pipe under mains pressure.

Where the mains pressure is excessive a pressure

reducing valve must be used to facilitate filling.

When installing the filling device it must be connected as

shown below, to fully comply with the water regulations.

This may involve the fitting of an additional WRAS

approved isolator valve to the mains supply.

i. Thoroughly flush out the whole system with

cold water.

ii. Fill and vent the system until the pressure

gauge registers 1.5 bar and examine for leaks.

iii. Check the operation of the safety valve by

raising the water pressure until the valve lifts.

This should occur within 0.3 bar of the preset lift

pressure.

iv. Release water from the system until the

minimum system design pressure is reached;

1.0 bar if the system is to be pre-pressurised.

Water Flow Rate and Pressure Loss

Max CH Output

kW

23.4

(Btu/h)

(80 000)

Water flow rate

l/sec

0.37

(gal/min)

4.8

Temperature Differential

o

C

15

(

o

F)

(27)

Head available for

m.w.g.

2.3

system pump.

(ft.w.g.)

7.5

DOMESTIC HOT WATER

1. The domestic hot water service must be in accordance

with BS 5546 and BS 6700.

2. Refer to Table 1 for minimum and maximum working

pressures.

3. The boilers are suitable for connection to most types of

washing machine and dishwasher appliances.

4. When connecting to suitable showers, ensure that:

a.

The cold inlet to the boiler is fitted with an approved

anti-vacuum or syphon non-return valve.

b.

Hot and cold water supplies to the shower are of equal

pressure.

5. Hard Water Areas

Where the water hardness exceeds 200mg/litre, it is

recommended that a proprietary scale reducing device is

fitted into the boiler cold supply within the requirements of

the local water company.

IMPORTANT

Provision MUST be made to accommodate the expansion of

DHW contained within the appliance, if a non-return valve is

fitted to the DHW inlet.

CH Return

Ecl 6053

Hose unions

Mains

water supply

Temporary hose

(disconnect after filling)

Additional

stop valve

Double check valve

assembly

(

note direction of flow

)

Summary of Contents for isar m30100

Page 1: ......