INSTALLATION

8

Harrier GT Range

- Installation

6

OIL OR GAS CONNECTION

See specific technical information supplied with the burner.

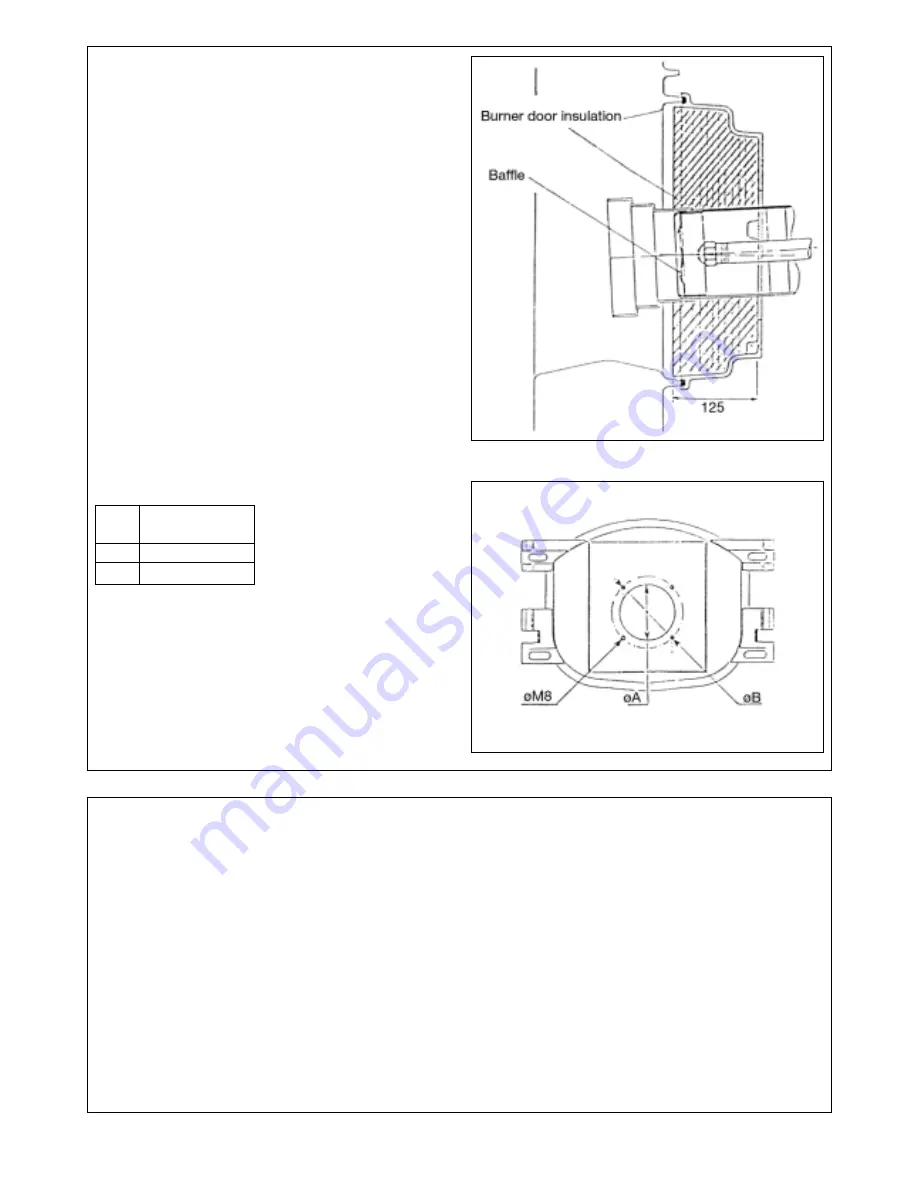

Burner positioning

Caution: the baffle at the head of the burner must be in line

with the burner door insulation level.

GAS SUPPLY

The gas supply MUST be sized in accordance with British

Gas recommendations and be fabricated in compliance with

CP.331 Pt. 3 and any Local Gas Board installation standards.

The Local Gas Board should be contacted, at a stage prior to

actual insallation, for any advice or information required.

Details and advice, relating to the use of L.PG. for firing the

IDEAL HARRIER GT range of heating boilers, are available on

request to Caradon Ideal Ltd.

OIL STORAGE TANK

The oil storage tank, oil supply pipe and connections to the

burner unit MUST comply with the requirements of BS. 779

and CP.541 0.

The installation should conform to the recognised standards

of good practice in the trade and comply with the relevant

Codes of Practice, Building Regulations and Local Authority,

Fire and insurance requirements.

8219-EN-22

8219-EN-61

Drilling ø for burner door:

Harrier GT

5 to 9 sections

ø A

135

ø B

170

7

ELECTRICAL CONNECTIONS TO THE CONTROL PANEL

CAUTION: The connection must be carried out by a

qualified professional.

As the electrical wiring has been carefully checked in the

factory, the internal connections of the control panel must

not be modified under any circumstances.

The electrical connections of the boiler must conform with

the lEE wiring regulations in force and with the specifications

shown on the electrical drawings provided with the

equipment, and the directions given below. The equipment

should be supplied by a circuit using an omnipolar circuit

breaker with an opening gap greater than 3 mm.