59

Operation manual geodyna 2350 - 9413 126

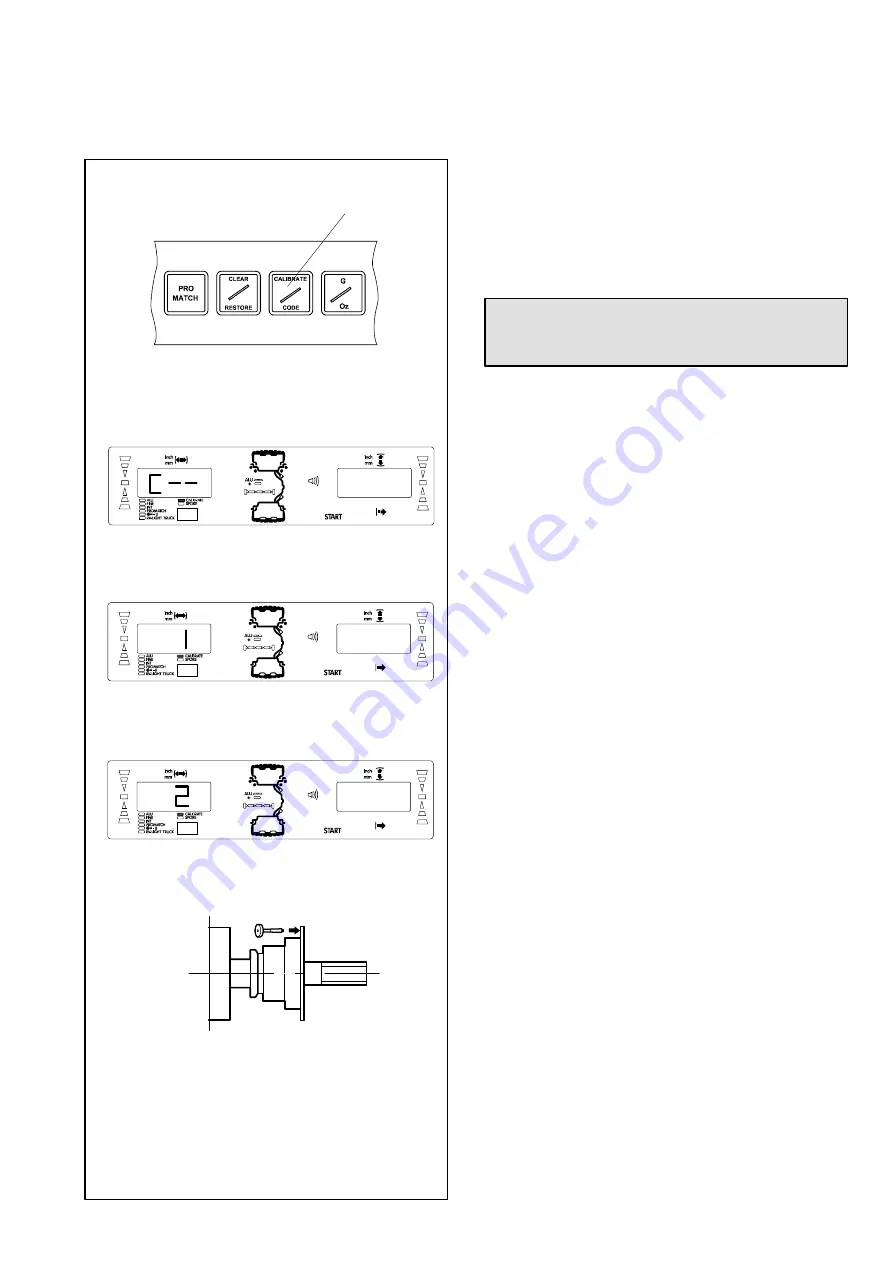

User calibration

135

136

137

138

139

1

.

.

13. User calibration

If several measuring runs are necessary to balance a wheel be-

cause balance weight size and position have to be changed re-

peatedly, it may be necessary to readjust the machine.

For readjustment by the operator a calibration weight is sup-

plied with the machine (ref. no. 6418 416 - kept on the rear of

the weight tray).

Important:

Readjustment must be carried out using the clamping

adapter supplied with the machine.

Readjustment

(Code C14)

D

Make sure no wheel or other clamping means is clamped

on the machine.

D

Press and hold the CODE key

(Fig. 135, pos. 1)

.

The basic reading C -- is read out

(Fig. 136)

.

D

Release the CODE key.

Reading 1. and START are read out

(Fig. 137)

.

D

Close the optional wheel guard, and press the START

key to carry out a readjustment run.

On completion of the first run reading 2. and START are read

out

(Fig. 138)

.

D

Screw the calibration weight into the threaded bore pro-

vided for this purpose in the basic body of the wheel

adapter

(Fig. 139)

.

D

Press the START key to carry out a second readjustment

run with the calibration weight fitted on the adapter (to de-

tect the correction values).

On completion of the processing operation a three-tone signal

is given and readjustment is completed. The machine is now

operative and the basic readings come back

(Fig. 135)

.

D

Remove the calibration weight from the wheel adapter

and put it back in its designated place.