16

01-1491-00-12.fm

Safety Instructions

1.6

Safety instructions for maintenance and servicing

General

•

Daily and weekly maintenance work must be done by the operating staff. In all other maintenance work, please

contact your nearest authorised Hako dealer.

•

Apart from the regular general inspection (HU), the vehicle, the attachments and the trolley must be

maintained at regular intervals according to BGV, D 29 and be checked at least annually for operationally safe

condition.

•

Risk of accident! Adopt measures against erroneous starting and unwanted movement. Operate the parking

brake. Switch the engine off and pull out the ignition key.

•

Spare parts must be original spare parts to guarantee safety.

•

Use suitable tools for the cleaning and maintenance work.

•

Cleaning the electrical and electronic components as well as the engine space with a high-pressure cleaner or

steam cleaner is not allowed.

•

Do not perform any welding, drilling, sawing or grinding work on parts of the frame. Damaged parts may be

replaced only by your authorised Hako dealer.

•

After cleaning, examine all fuel, engine oil and hydraulic pipes for leaks, abrasion places and damage.

Immediately rectify any damage found!

•

Always tighten screw connections loosened in maintenance and repair work.

•

If dismantling safety devices is required in equipping, maintenance and repair work, fit and check the safety

devices immediately after completion of the work.

•

Perform maintenance and repair work under a jacked up vehicle or attachment only if it is safely and securely

supported (hydraulic cylinders, jacks, etc. alone do not secure a jacked-up vehicle).

Engine

•

Toxic engine exhaust gases! Inhaling exhaust gases is injurious to health and can lead to unconsciousness

and to death! Never let the engine run in enclosed spaces.

•

Danger of burns from hot parts! Do not touch any parts such as engine block, cooling system and exhaust

system during operation and for some time after. Let the engine cool down.

•

Risk of injury due to rotating parts of the cooling system. Injury of limbs or hair or clothing getting caught up.

Switch the engine off and pull out the ignition key.

•

If the engine oil pressure warning symbol in the multifunction display lights up with the engine running, there is

a risk of engine damage! Stop the vehicle in the safe range. Turn the engine off immediately and check the oil

level. Have the cause of the inadequate engine oil pressure removed.

•

If the diesel particulate filter in the multifunction display lights up red, the vehicle engine must be switched off

immediately. Serious engine damage can be caused if this is not complied with.

Fuel system

•

Risk of fire! Diesel fuel is flammable! Take the utmost care when handling fuel. Never refuel close to naked

flames or ignitable sparks. Do not smoke during fuelling. Switch off the engine, pull out the ignition key and

apply the parking brake before fuelling.

•

Danger of burns from hot parts! Do not touch any parts such as engine block, cooling system and exhaust

system during operation and for some time after. Let the engine cool down.

•

There is a risk of engine damage if the fuel system is run completely empty! Inform an authorised workshop!

Diesel particulate filter

•

Danger of fire and burning! The diesel particulate filter gets very hot. Do not grasp in the area of the diesel

particulate filter. Do not park the vehicle in the direct vicinity of flammable substances.

Cooling system

•

Danger of burns from hot parts! Do not touch any parts such as engine block, cooling system and exhaust

system during operation and for some time after. Let the engine cool down.

•

Risk of scalding from hot coolant! The cooling system is under pressure. If the cooling system cap is opened

with a hot engine there is a risk of scalding. Let the engine cool down.

•

Risk of injury due to rotating parts! Injury of limbs or hair or clothing getting caught up. Switch the engine off

and pull out the ignition key.

•

The cooling fins are very thin and can be damaged easily.

•

Small air bubbles can form when the radiator is filled. Therefore the cooling system must be vented at the

same time. Have this done by an authorised workshop!

Summary of Contents for Citymaster 1600

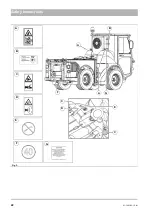

Page 22: ...22 01 1491 00 12 fm Safety Instructions G A B D E F Fig 3 C F C E C D G A B A...

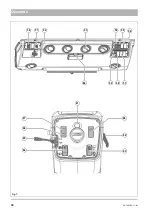

Page 26: ...26 02 1491 00 11 fm Operation Fig 5 25 23 16 18 17 19 22 21 20 24 26 27...

Page 30: ...30 02 1491 00 11 fm Operation Fig 7 62 63 61 67 55 50 51 54 53 52 58 57 59 60 65 64 66 68 56...

Page 32: ...32 02 1491 00 11 fm Operation Fig 8 75 69 78 73 72 79 80 81 82 83 74 77 70 71 76 84...

Page 85: ...04 1491 00 11 fm 85 Technical Data 4 Technical Data Fig 80 3830 1600 941 1210 975 1964...

Page 146: ...146 06 1491 00 12 fm Attachments and Options 6 1 5 Technical data Fig 144 2215 4510 1580 2250...

Page 220: ...220 06 1491 00 12 fm Attachments and Options...