-90-

Model G0853 (Mfd. Since 07/18)

Belt Service

The belts will stretch slightly as the saw is used.

Most of the stretching will occur during the first

16 hours of use, but it may continue through con-

tinued use. To maintain efficient power transfer

to the blades, make sure the belts are properly

tensioned and in good condition. If belts show any

glazing, fraying, or cracking, replace them.

Replacing Scoring Motor Belt

To replace the scoring motor belt, tilt the blade to

45°, have an assistant lift the scoring motor up to

relieve the belt tension, then replace the belt with

a new one. When the motor is lowered, proper

belt tension will be applied by the spring.

Tensioning Scoring Motor Belt

Proper tension of the scoring motor flat belt is

automatically maintained by a spring on the motor

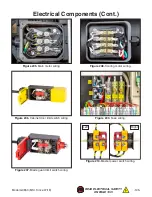

pivot rod (see

Figures 180–181).

Tensioning Main Motor Belt

Proper tension of the main motor belt is automati-

cally maintained by a cam lock attached to the

motor mounting plate and arbor support bracket

(see

Figure 182).

To reduce risk of shock or

accidental startup, always

disconnect machine from

power before adjustments,

maintenance, or service.

Figure 181. Location of scoring motor spring.

Scoring Motor

Spring

Figure 180. Location of scoring motor flat belt.

Scoring Motor

Flat Belt

Figure 182. Location of main motor belt and

cam lock (table removed for clarity).

Cam Lock

Main Motor

Belt

Summary of Contents for G0853

Page 24: ...22 Model G0853 Mfd Since 07 18 5mm Hardware Recognition Chart...

Page 140: ......