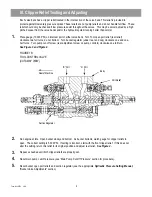

VI. Swing Pump Centering (Mechanical)

The swing pump has adjustments for mechanical centering of the swash plate. This adjustment should be made

with the bucket firmly on the ground and all controls in neutral.

With the engine off, install 10,000 PSI gauges on each high pressure port. (M5 & M6).

See Figure 2 & Figure IA.

Remove plugs X3 & X4 and install a one quarter inch (1/4") hose to connect both sides of the pump

stroking piston.

Start engine and run at full RPM (2400 RPM).

Gauges should read 380-420 PSI equally.

If gauges are not equal, adjust the (entering screw until pressure rises on one gauge. After pressure rise is

determined, counting the number of turns required, adjust the centering screw in the opposite direction until the

second gauge pressure rises.

Turn the adjusting screw approximate to the halfway point, where the gauges should read equal.

Do not actuate swing. This will destroy the pressure gauges.

1.

2.

3.

4.

5.

6.

!

WARNING

XL 4000/XL 5000 SERIES

HYDRAULIC PRESSURE SETTING MANUAL

(Supplemental Pressures)

Form No. 29705 3/99

11

Summary of Contents for XL4000

Page 2: ......

Page 73: ......

Page 76: ... 5MP ...

Page 145: ......

Page 146: ......

Page 160: ......

Page 161: ......

Page 162: ......

Page 175: ......

Page 176: ......

Page 177: ......

Page 178: ......

Page 192: ......

Page 193: ......

Page 194: ......

Page 207: ......

Page 208: ......

Page 210: ...500P ...

Page 229: ......

Page 230: ......

Page 245: ......

Page 246: ......

Page 247: ......

Page 248: ......

Page 265: ......

Page 266: ......

Page 267: ......

Page 268: ......

Page 280: ......

Page 281: ......

Page 282: ......

Page 297: ......

Page 298: ......

Page 299: ......

Page 300: ......

Page 301: ......

Page 302: ......

Page 303: ......

Page 304: ......