75

Fig. 37.

The electrode assembly

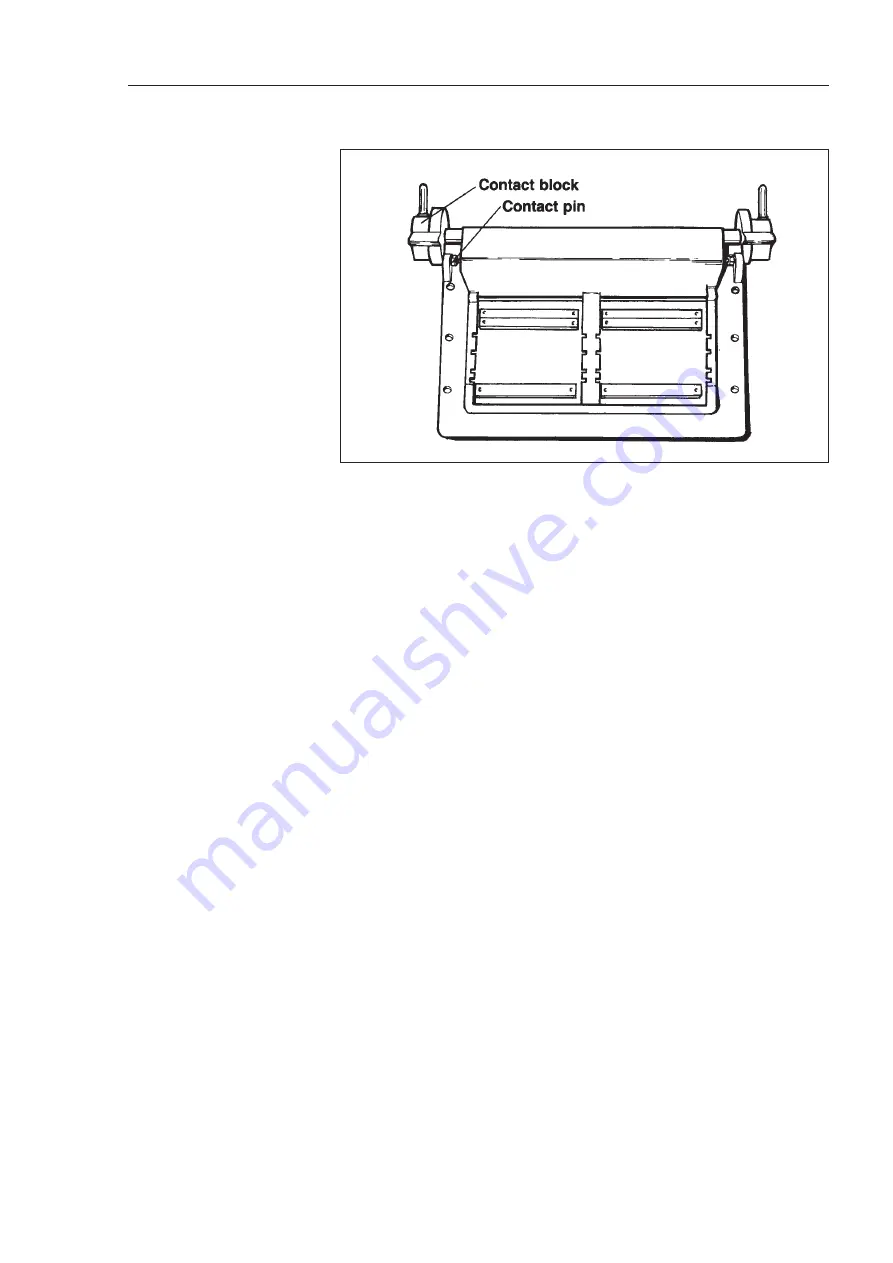

Replacing the contact pieces

The contact blocks and pins should be replace when damaged. When

you have pulled out the applicator arm and electrode assembly unit,

lay it down on a table and pull out the contact blocks. Replace the

blocks and fit the eccentric levers into place. It might help to move the

lever a little back and forth until it slips into place.

When you replace one contact pin, always replace the other.

Replacing the separation bed cover

The separation bed cover should be replaced if the surface has been

damaged by burns or deep scratches.

Remove the damaged cover by lifting one of the edges up with a

scalpel and peeling the cover off. If there is any glue left on the

cooling plate, remove it by moistening a piece of cloth in an adhesive

solvent, e.g. terpentine, or ligroin, and tuck it down into the recess.

The cloth must be drip-free, solvent might otherwise dissolve the

insulation below the separation bed. Rub gently or leave it on for

about one hour to dissolve the old adhesive.

Wipe away the old adhesive, and clean the bed thoroughly; the new

gel bed cover must lie perfectly flat against the bed.

The spare separation bed cover is self-adhesive. Peel back the paper

backing along the anode (+) side about 2-3 cm. Put this end against

the rear edge in the recess and fold it down carefully. Press along this

piece with your thumb to ensure good contact with the bed. Peel back

the paper backing another 2-3 cm, and press along this piece with

your thumb. Be careful not to trap air bubbles between the bed and

the bed cover. (If air bubbles are present you will have to try again with

a new bed cover.) Continue peeling back the paper backing and

smoothing out the bed cover until the recession is covered.

7. Maintenance and trouble shooting