K0430 Issue No. 2

54

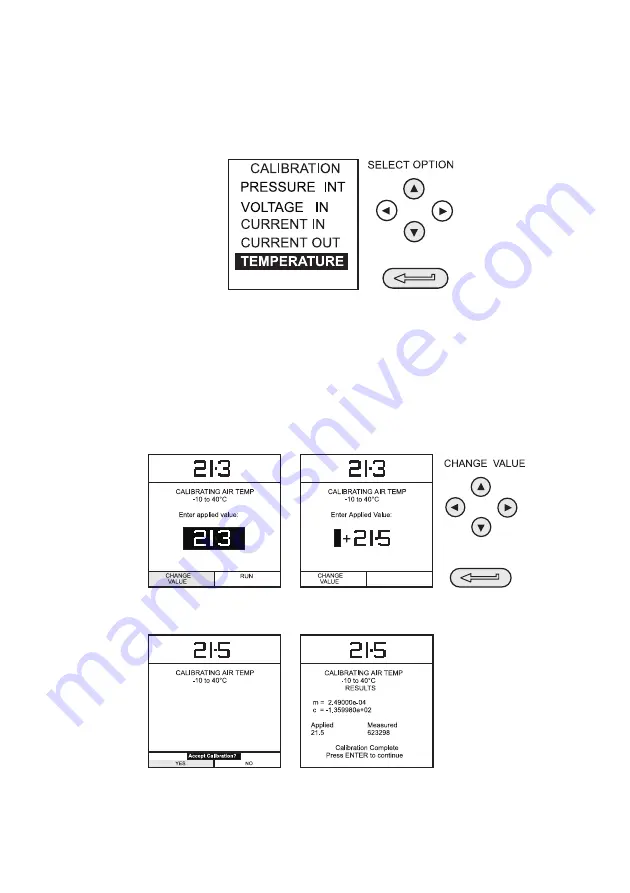

Ambient Temperature Channel

Use the following procedure for calibrating the ambient temperature measurement

channel.

(1)

Switch the instrument on, enter the

CALIBRATION

mode and select

TEMPERATURE

:

(2)

Allow the instrument’s temperature to stabilize in the calibration environment for

at least one hour.

(3)

Read the environmental temperature on a calibrated digital thermometer and

enter the recorded value as shown below. Example shown for a measured

ambient temperature of 21.5° Celsius.

Note:

Only one temperature point is required.

(4)

Press the

ENTER

key to accept the calibration. Press the

EXIT

key once to return

to the calibration menu or four times to quit the

CALIBRATION

and

SETUP

modes.

Calibration

Summary of Contents for Druck DPI 615 IS

Page 3: ...K0430 Issue No 2 ii ...

Page 66: ...57 K0430 Issue No 2 Hydraulic Calibrator Versions 3 ...

Page 67: ...K0430 Issue No 2 58 This page intentionally left blank ...

Page 73: ...K0430 Issue No 2 64 This page intentionally left blank ...

Page 74: ...65 K0430 Issue No 2 Appendix 1 DATA LOG FILE EXAMPLE ...

Page 78: ...69 K0430 Issue No 2 Appendix 2 ATEX Certificate of Conformity ...

Page 79: ...K0430 Issue No 2 70 intentionally left blank ...

Page 80: ...71 K0430 Issue No 2 ...

Page 81: ...K0430 Issue No 2 72 ...

Page 82: ...73 K0430 Issue No 2 ...

Page 83: ...K0430 Issue No 2 74 ...

Page 84: ...75 K0430 Issue No 2 ...

Page 86: ...77 K0430 Issue No 2 ...

Page 87: ...K0430 Issue No 2 78 ...

Page 88: ...79 K0430 Issue No 2 ...

Page 89: ...K0430 Issue No 2 80 ...

Page 90: ...81 K0430 Issue No 2 ...

Page 91: ...K0430 Issue No 2 82 ...

Page 92: ...83 K0430 Issue No 2 ...

Page 93: ...K0430 Issue No 2 84 ...

Page 94: ...85 K0430 Issue No 2 ...